- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

2025 Top Digital Metal Machining Equipment Trends You Need to Know

As we move closer to 2025, the landscape of metal machining equipment is undergoing significant transformation driven by technological advancements and industry demands. According to a report by Allied Market Research, the global metal machining market is expected to reach $282 billion by 2026, growing at a CAGR of 5.6% from 2019. This robust growth is largely influenced by the increasing automation in manufacturing processes and the demand for precision in metal fabrication. In this context, staying updated with the top trends in metal machining equipment becomes crucial for industries aiming to enhance productivity and competitiveness.

The integration of advanced technologies such as additive manufacturing, artificial intelligence, and IoT is reshaping the capabilities and functionalities of metal machining equipment. Industry analysts from Technavio predict that by 2025, approximately 15% of metal machining equipment will be integrated with AI and machine learning, leading to smarter production lines that can adapt to varying operational demands. Furthermore, sustainability concerns are propelling innovations in energy-efficient machinery, as companies seek to minimize their environmental footprint while maximizing output. As we explore the "2025 Top 10" trends, it is essential for stakeholders in the metal machining sector to recognize these shifts and invest in cutting-edge equipment that meets future market needs.

Table of Contents

[Hide]

Emerging Technologies in Digital Metal Machining for 2025

As we approach 2025, digital metal machining stands poised for transformative advancements driven by emerging technologies. One of the most significant trends is the integration of artificial intelligence (AI) and machine learning algorithms into machining processes. These technologies enable real-time data analysis, enhancing precision and efficiency. With AI-powered systems, manufacturers can predict equipment wear and optimize maintenance schedules, thus reducing downtime and operational costs.

Tips: To stay ahead in this evolving landscape, consider investing in training programs for your workforce that focus on AI applications in machining. This not only prepares your team for new technologies but also encourages a culture of innovation within your organization.

Another noteworthy development is the rise of additive manufacturing techniques, such as metal 3D printing. This technology allows for the creation of complex geometries that traditional machining cannot achieve. As a result, businesses can reduce material waste and shorten production times.

Tips: Explore partnerships with tech startups to leverage these innovative manufacturing processes. Collaboration can lead to unique solutions tailored to your specific production needs, fostering a competitive edge.

Integration of AI and Machine Learning in Machining Processes

The integration of artificial intelligence (AI) and machine learning in machining processes is revolutionizing the digital metal machining landscape. These technologies enable manufacturers to analyze vast amounts of data generated during production, thereby optimizing machining parameters in real-time. By leveraging predictive analytics, companies can foresee equipment failures, allowing for preventative maintenance that minimizes downtime and maximizes operational efficiency.

Moreover, AI-driven solutions can enhance precision and quality in machining operations. With machine learning algorithms, systems can learn from past performance and improve their decision-making capabilities. This allows for adaptive machining processes that can adjust to varying material properties and tool wear conditions, resulting in higher quality outcomes and reduced waste. As these innovations continue to evolve, the future of digital metal machining will increasingly rely on intelligent systems that not only streamline operations but also enhance overall productivity.

Trends in Digital Metal Machining Equipment for 2025

Sustainability Trends in Digital Metal Fabrication Equipment

As the manufacturing industry evolves, sustainability in digital metal fabrication equipment emerges as a crucial trend for 2025. Recent analyses suggest that the sheet metal fabrication services market is projected to grow significantly, from $35.51 billion in 2025 to $61.78 billion by 2032, reflecting a compound annual growth rate (CAGR) indicating a robust demand for more eco-friendly practices. Manufacturers are increasingly seeking advanced technologies that not only improve efficiency but also minimize environmental impact through reduced waste and optimized resource utilization.

The integration of artificial intelligence (AI) into manufacturing processes further enhances sustainability efforts. AI-driven analytics enable manufacturers to identify inefficiencies and reduce energy consumption, reinforcing a commitment to sustainable practices. Moreover, the emergence of digital twins is helping organizations refine their production processes, ultimately boosting the sustainability of operations. As the semiconductor industry embraces similar principles with sustainable chip production methods, the overall trend towards an eco-conscious approach in digital metal machining equipment is expected to gain momentum, setting the stage for innovative solutions in the manufacturing landscape.

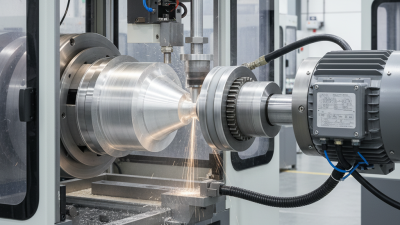

Advancements in Automation and Robotics for Metal Machining

The advancements in automation and robotics are revolutionizing the metal machining industry, underscored by significant market growth projections. The global metal fabrication equipment market is anticipated to expand from $64.64 billion in 2025 to $82.78 billion by 2032, reflecting a compound annual growth rate (CAGR) of 3.6%. Concurrently, the industrial robotics sector is booming, with a market valuation of $87.1 billion in 2024 projected to soar to $162.7 billion by 2030, showcasing a robust CAGR of 11.0%. These figures highlight the urgency for companies to integrate robotic solutions into their manufacturing processes.

The advancements in automation and robotics are revolutionizing the metal machining industry, underscored by significant market growth projections. The global metal fabrication equipment market is anticipated to expand from $64.64 billion in 2025 to $82.78 billion by 2032, reflecting a compound annual growth rate (CAGR) of 3.6%. Concurrently, the industrial robotics sector is booming, with a market valuation of $87.1 billion in 2024 projected to soar to $162.7 billion by 2030, showcasing a robust CAGR of 11.0%. These figures highlight the urgency for companies to integrate robotic solutions into their manufacturing processes.

Amidst this transformation, machine vision technology is playing a pivotal role in enhancing robotic automation. It improves precision, speed, efficiency, and the adaptability of machines across various industrial applications. As robotics become more intelligent, powered by the rapid advancements in artificial intelligence, manufacturers can expect higher operational efficiency and optimized production.

Amidst this transformation, machine vision technology is playing a pivotal role in enhancing robotic automation. It improves precision, speed, efficiency, and the adaptability of machines across various industrial applications. As robotics become more intelligent, powered by the rapid advancements in artificial intelligence, manufacturers can expect higher operational efficiency and optimized production.

Tips: To stay ahead in this evolving landscape, businesses should consider investing in training for staff on automated systems and machine vision technology. Additionally, regular assessments of current machinery can help identify areas where robotics can be effectively implemented for maximum benefit. Embracing these innovations will not only boost productivity but also prepare companies for future industrial challenges.

Cloud Computing and Data Analytics in Metal Manufacturing Operations

The digital transformation of the metals manufacturing industry is increasingly reliant on cloud computing and data analytics, which are critical to enhancing operational efficiency. By leveraging these technologies, manufacturers can harness real-time data to optimize production processes, reducing downtime and waste. The integration of AI and machine learning within this framework allows for predictive maintenance and improved decision-making, providing companies with a competitive edge in an evolving market.

Moreover, adopting smart digital practices contributes significantly to sustainability efforts in metals manufacturing. Innovative solutions, such as energy management systems and resource optimization tools, enable organizations to minimize their environmental impact while maximizing productivity. As the industry adapts to these digital trends, businesses not only enhance their operational capabilities but also align with global sustainability goals, showcasing a commitment to responsible manufacturing practices. This strategic shift represents both a challenge and an opportunity for manufacturers looking to thrive in the digital age.

Related Posts

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

What is Aluminium Spinning Machine and How Does it Work

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023

-

Top 5 Metal Roll Forming Machines for Precision Manufacturing in 2023

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry