- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

How to Effectively Use Spin Forming Metal Techniques in Manufacturing

In the realm of modern manufacturing, the utilization of advanced techniques plays a crucial role in enhancing efficiency and precision. One such technique that stands out for its versatility and effectiveness is spin forming metal. This innovative method allows manufacturers to create complex shapes and structures with outstanding accuracy while minimizing waste. As industries increasingly demand lightweight and durable components, understanding how to effectively implement spin forming metal techniques has become essential for achieving optimal results in production processes.

Spin forming metal is not only about shaping materials; it encompasses a range of tactical approaches that can be tailored to meet specific design requirements. By mastering the principles of this technique, manufacturers can streamline operations, reduce costs, and improve product quality. The introduction of automation and advanced tooling further elevates the spin forming process, enabling the production of intricate designs that were once deemed impractical.

In conclusion, the strategic use of spin forming metal in manufacturing opens up new avenues for innovation and efficiency. As businesses aim to stay competitive in a fast-evolving market, adopting these techniques will be paramount to meet the growing demands for more sophisticated and economically viable solutions.

Table of Contents

[Hide]

Understanding Spin Forming: Definition and Principles

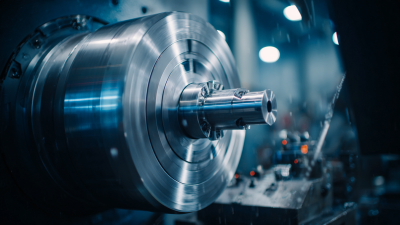

Spin forming is a specialized metalworking process that involves shaping metal into desired forms using rotational force. At its core, the technique relies on the principles of centrifugal force, which allows a cylindrical blank to be manipulated into complex geometric shapes. The process begins with a flat metal disk (the blank) mounted onto a spindle. As the spindle rotates, a tool is applied to the surface of the metal, gradually reshaping it into the final profile. This method is particularly well-suited for producing hollow components such as cones, cups, and domes with excellent dimensional accuracy and surface finish.

One of the key advantages of spin forming lies in its efficiency and versatility. The process is capable of handling a wide variety of materials, including aluminum, copper, and stainless steel, making it ideal for diverse manufacturing applications. Moreover, because spin forming focuses on the use of high rotational speeds and controlled pressure, it minimizes material wastage, which is a significant benefit in terms of cost-efficiency. Designers and engineers can leverage spin forming to create lightweight yet durable parts, allowing for innovation in product design without compromising on quality or performance.

Advantages of Spin Forming in Metal Manufacturing

Spin forming, a technique employed in metal manufacturing, offers several distinct advantages that set it apart from traditional methods. By utilizing a spinning motion to shape metal, manufacturers can achieve complex geometries with relative ease. One of the foremost benefits of spin forming is its ability to produce high-quality components with reduced material wastage. The process allows for the efficient use of raw materials, as it often requires less material to achieve the desired thickness and shape compared to other forming methods.

Another significant advantage of spin forming is the enhanced mechanical properties it imparts to the finished products. As the spinning process induces stresses within the metal, it can lead to improved strength and durability. This is particularly beneficial in industries where components are subjected to high levels of stress or extreme conditions. Additionally, the capabilities of spin forming enable manufacturers to achieve fine details and smooth surface finishes, providing aesthetic and functional benefits that contribute to the overall quality of the product.

Moreover, spin forming allows for greater flexibility in design and production runs. It is well-suited for both small batches and large-scale manufacturing, making it an attractive option for businesses looking to adapt to changing market demands. The versatility of spin forming techniques can also accommodate various materials, making it a suitable choice for a wide range of applications across different industries. These advantages collectively position spin forming as a valuable technique in modern metal manufacturing, driving efficiency and innovation.

How to Effectively Use Spin Forming Metal Techniques in Manufacturing - Advantages of Spin Forming in Metal Manufacturing

| Technique | Advantages | Applications | Materials Used |

|---|---|---|---|

| Traditional Spin Forming | Cost-effective for high volume production | Automotive parts, Aerospace components | Aluminum, Stainless Steel |

| Hydraulic Spin Forming | Uniform wall thickness, Reduced material waste | Turbine housings, Pressure vessels | Copper, Titanium |

| Electromagnetic Spin Forming | High precision and flexibility | Medical devices, Specialty fasteners | Magnesium, Brass |

| CNC Spin Forming | Complex geometries and designs | Custom art installations, Unique architectural elements | Carbon Steel, Alloy Steel |

Essential Tools and Equipment for Spin Forming

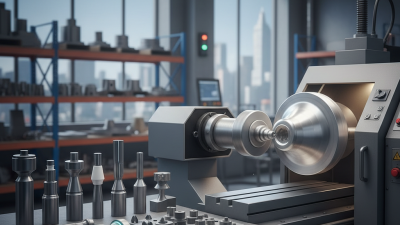

Spin forming is a highly efficient metal forming technique that involves rotating a metal disk over a mold to create complex geometries. To effectively employ this technique in manufacturing, it is essential to have the right tools and equipment at hand. Key equipment includes a spin forming lathe, which is the centerpiece of the operation. According to a 2021 report by the Metal Forming Association, as much as 30% of manufacturing costs can be reduced by optimizing tooling and machinery settings without compromising the quality of the produced parts.

In addition to the lathe, other crucial tools include a variety of rollers, which are instrumental for shaping the metal during the spinning process. The use of high-quality rollers can significantly impact the precision of the formed parts, as noted in the International Journal of Advanced Manufacturing Technology. Furthermore, proper clamps and fixtures are vital for securing the workpiece in place, ensuring consistent results.

As the market for fabricated metal products is projected to reach $100 billion in 2023, investing in the right spin forming tools and equipment is key for manufacturers looking to enhance productivity and product quality.

Step-by-Step Process of Spin Forming Techniques

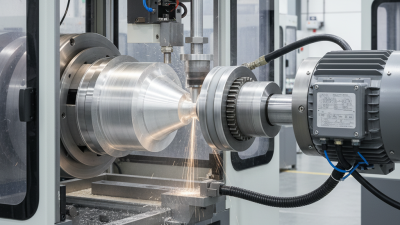

Spin forming is a highly efficient metal forming technique that allows for the creation of complex shapes from flat metal sheets. To effectively use spin forming in manufacturing, it's essential to understand the step-by-step process involved. First, the metal sheet is clamped to a rotating spindle. As the spindle spins at high speeds, a forming tool applies pressure to the material, forcing it to conform to the desired shape. Data from industry reports indicate that spin forming can achieve tolerances as tight as ±0.005 inches, making it an excellent choice for precision components.

The next steps involve adjusting the tooling and process parameters to ensure optimal results. Manufacturers typically begin with a prototype run to test the parameters based on the material properties and the final design specifications. According to a report by the Manufacturing Institute, companies utilizing advanced forming techniques like spin forming can enhance production efficiency by up to 30%. Once the parameters are refined, the scaling to full production can be initiated, focusing on maintaining quality and consistency throughout the batch. Regular assessment of the formed parts through non-destructive testing is recommended to ensure adherence to industry standards and customer specifications.

Metal Spin Forming Production Efficiency

Applications of Spin Forming in Various Industries

Spin forming is a versatile metal forming technique utilized across various industries due to its efficiency and ability to create complex shapes. Common applications include aerospace, automotive, and decorative metalwork. In the aerospace sector, spin forming is used to produce lightweight but strong components such as fuel tanks and fairings, which require precise dimensions and excellent surface finishes. In the automotive industry, it aids in creating parts like wheels and exhaust systems, which benefit from the technique’s ability to work with different materials including aluminum and stainless steel.

Tips for implementing spin forming techniques include careful material selection and maintaining consistent tooling. Choosing the right alloy can significantly impact the final product's durability and weight, especially in applications where performance is critical. Additionally, ensuring that tools are regularly maintained and calibrated can reduce deviations during the forming process, leading to better quality and lower waste.

Tips for implementing spin forming techniques include careful material selection and maintaining consistent tooling. Choosing the right alloy can significantly impact the final product's durability and weight, especially in applications where performance is critical. Additionally, ensuring that tools are regularly maintained and calibrated can reduce deviations during the forming process, leading to better quality and lower waste.

Another important consideration is the design of parts. Engineers should take advantage of spin forming’s ability to create symmetrical shapes, which not only optimizes material usage but also enhances aesthetic appeal. For successful applications, collaboration between designers and production teams is essential to ensure designs are feasible for spin forming, ultimately leading to innovative applications across various industries.

Another important consideration is the design of parts. Engineers should take advantage of spin forming’s ability to create symmetrical shapes, which not only optimizes material usage but also enhances aesthetic appeal. For successful applications, collaboration between designers and production teams is essential to ensure designs are feasible for spin forming, ultimately leading to innovative applications across various industries.

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

What is Aluminium Spinning Machine and How Does it Work

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023