- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

In the evolving landscape of manufacturing, "denn metal spinning" stands out as a crucial technique that enhances efficiency and precision in the production of metal components. Industry expert John Smith, a distinguished figure with over two decades of experience in metalworking, emphasizes, "The mastery of denn metal spinning lies in understanding its intricate techniques, which not only streamline production but also significantly reduce material waste." This innovative process involves shaping metal into desired forms by rotating it against a stationary tool, resulting in high-quality products with minimal imperfections.

The advantages of denn metal spinning are manifold; it offers flexibility in design, the ability to work with various materials, and a cost-effective approach for small to medium production runs. As industries continue to seek sustainable and efficient manufacturing solutions, the adoption of advanced techniques in denn metal spinning is becoming increasingly pivotal. By harnessing the benefits of this method, manufacturers can not only enhance their operational efficiency but also meet the growing demand for customized metal products. In this article, we will explore the best tips for efficient denn metal spinning, uncovering the techniques that can lead to superior outcomes in production.

Table of Contents

[Hide]

Understanding Denn Metal Spinning and Its Applications

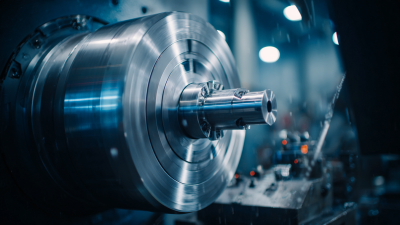

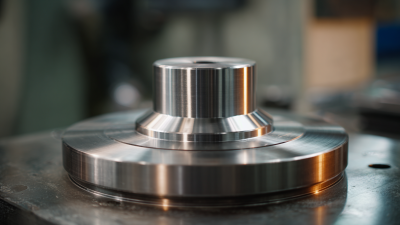

Denn metal spinning is a versatile manufacturing process that involves shaping a metal disc into a desired form by rotating it on a spindle and applying pressure with a tool. This technique is particularly valuable in producing cylindrical parts with complex geometries, making it widely applicable in various industries such as aerospace, automotive, and consumer goods. The process is well-suited for creating items ranging from simple bowls to intricate components, and its ability to produce lightweight yet durable structures makes it an attractive option for modern engineering.

One of the key advantages of Denn metal spinning is its efficiency in material usage. Unlike traditional machining methods that often generate significant scrap metal, spinning utilizes a whole metal sheet, which minimizes waste and lowers costs. Additionally, because the process can be performed using both manual and automated systems, manufacturers have the flexibility to choose the approach that best suits their production needs. The adaptability in terms of material types, thickness, and designs allows for tailored solutions that meet specific application requirements, making Denn metal spinning an essential technique in contemporary manufacturing processes.

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| Spindle Speed Optimization | Adjusting spindle speed for different materials to improve results. | Enhanced precision and reduced material waste. | Aerospace, Automotive |

| Tool Selection | Using the right tools for specific metal types improves efficiency. | Reduced wear on tools and better surface finish. | Manufacturing, Custom Parts |

| Lubrication Techniques | Employing the right lubricants to facilitate metal forming. | Improved tooling life and lower friction. | Heavy Equipment, Electronics |

| Process Monitoring | Using sensors to monitor the spinning process in real-time. | Immediate feedback for adjustments leads to higher quality. | Medical Devices, Aerospace Components |

| Batch Production | Efficiently producing multiple parts in a single run. | Cost-effective and time-saving. | Various Industries, Custom Manufacturing |

Key Techniques for Efficient Denn Metal Spinning

When it comes to efficient Denn metal spinning, mastering key techniques is essential for optimal results. One of the most important techniques is controlling the speed and feed rate during the spinning process. By adjusting these parameters based on material properties and part design, manufacturers can reduce waste and ensure uniform thickness. Employing a higher speed can increase productivity, but it must be balanced with appropriate feed rates to prevent material fatigue or damage.

Another crucial technique is the use of proper tooling. High-quality, precisely engineered tools not only enhance the accuracy of the finished products but also lead to a longer lifespan for the tooling itself. The choice of tool geometry and material plays a significant role in the effectiveness of the spinning process. Additionally, incorporating advanced CNC machinery can facilitate complex designs and improve repeatability, making it easier to achieve consistent output with minimal manual intervention. By focusing on these core techniques, manufacturers can achieve greater efficiency and quality in Denn metal spinning operations.

Advantages of Denn Metal Spinning in Manufacturing

Denn metal spinning offers several advantages that position it as a highly efficient and versatile manufacturing technique. One of the primary benefits is its ability to produce complex shapes with minimal material waste. According to industry reports, traditional machining methods can generate waste material up to 70%. In contrast, Denn metal spinning can achieve waste rates as low as 5%, making it not only cost-effective but also more environmentally friendly. This efficiency in material usage is particularly significant in industries where raw material costs are high, such as aerospace and automotive sectors.

Moreover, Denn metal spinning enables rapid production times without compromising the structural integrity of the final product. Research has shown that parts created through metal spinning can be produced up to 50% faster than those manufactured through traditional CNC machining. This speed, combined with the capability to work with a variety of materials—including aluminum, steel, and titanium—offers manufacturers a flexible solution to meeting diverse project requirements. The improved cycle times lead to reduced lead times, allowing companies to respond more swiftly to market demands while maintaining high quality standards. Therefore, the advantages of Denn metal spinning not only enhance operational efficiency but also contribute significantly to improving overall productivity within the manufacturing landscape.

Benefits of Denn Metal Spinning in Manufacturing

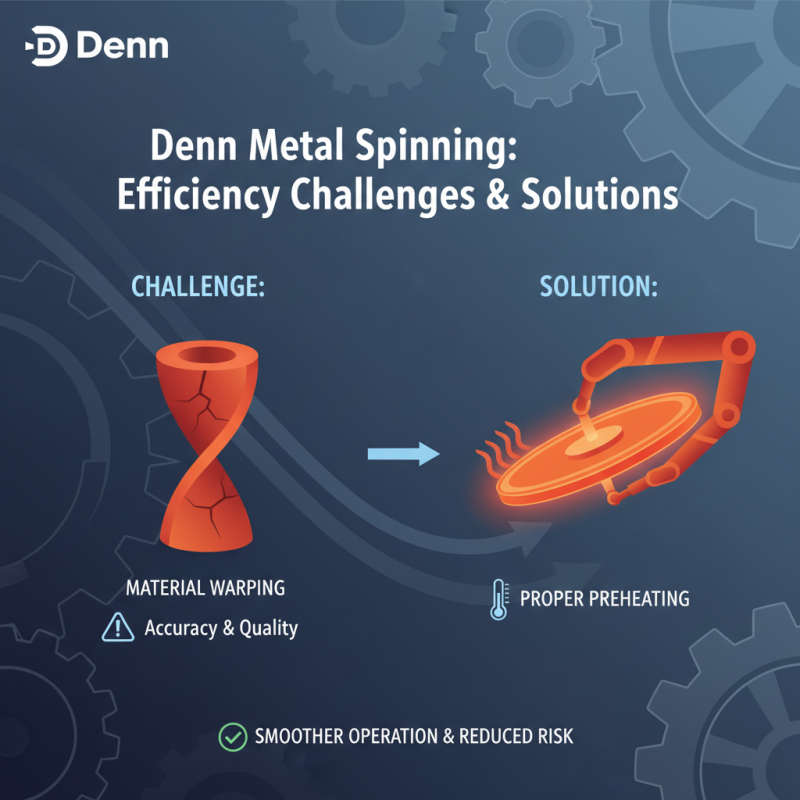

Common Challenges in Denn Metal Spinning and Solutions

In the world of Denn metal spinning, achieving high levels of efficiency often comes with its own set of challenges. One common issue faced during the spinning process is material warping, which can affect the accuracy and quality of the final product. To counter this, it’s essential to ensure that the metal is preheated properly before forming. Heat helps the material become more malleable, reducing the risk of warping and ensuring a smoother spinning operation.

Another challenge is maintaining the correct speed and pressure throughout the spinning process. If the speed is too high or the pressure is insufficient, it can lead to uneven thickness and surface defects. A good practice is to perform regular checks and adjustments during the spinning to ensure consistent results. Additionally, experimenting with different tooling designs can help in achieving a more controlled spinning process.

For maximum efficiency, it’s beneficial to invest time in training operators on best practices. Knowledge about proper tooling, machine setup, and maintenance can significantly reduce errors and downtime. Regularly reviewing techniques and incorporating feedback will help in streamlining operations, ultimately leading to a more productive and efficient metal spinning process.

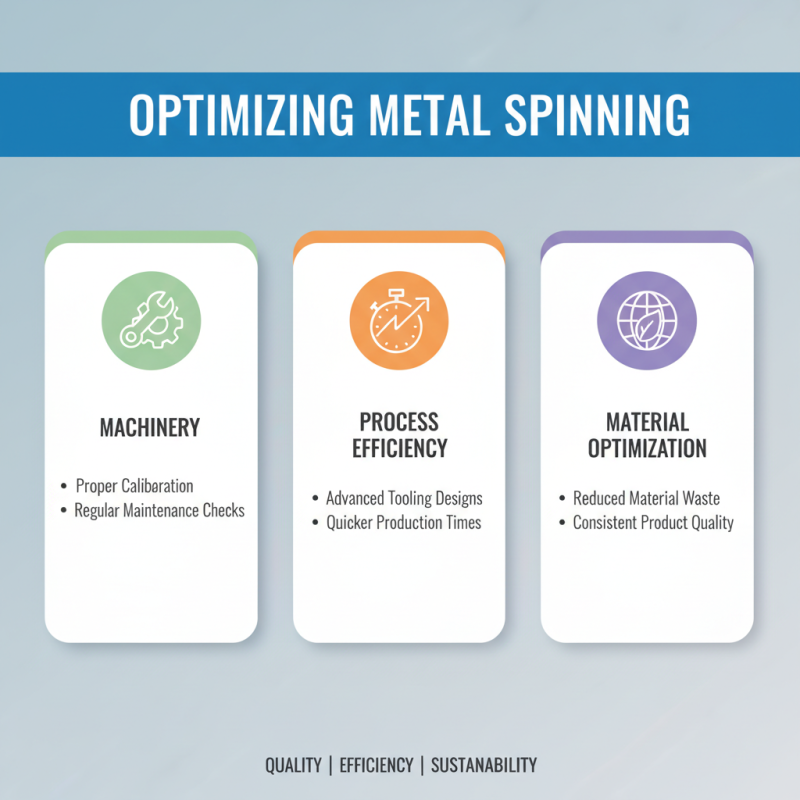

Best Practices for Optimizing Metal Spinning Processes

Optimizing metal spinning processes requires a deep understanding of both the techniques involved and the equipment used. One crucial best practice is to ensure that the machinery is properly calibrated and maintained. Regular maintenance checks can prevent unwanted downtime and ensure consistent quality in the finished products. Additionally, utilizing advanced tooling designs can improve the efficiency of the spinning process, allowing for quicker production times and reducing material waste.

Another effective strategy is to invest in training for operators. Skilled workers are essential in maximizing the potential of metal spinning machines. By fostering an environment of continuous learning, companies can keep their workforce updated on the latest techniques and technology, which ultimately enhances productivity. Moreover, establishing a feedback loop where employees can share insights on process improvements can lead to innovative solutions that benefit the overall workflow.

Finally, employing simulation software can play a significant role in optimizing operations. By modeling different spinning scenarios, businesses can foresee challenges and make informed decisions before production begins. This proactive approach minimizes errors and increases efficiency, leading to sustainable practices that can enhance both output and performance in the long run.

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

How to Effectively Use Spin Forming Metal Techniques in Manufacturing

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

Top 5 Metal Roll Forming Machines for Precision Manufacturing in 2023

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know