- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

10 Essential Tips for Mastering Metal Flow Forming Techniques

In the ever-evolving landscape of manufacturing, metal flow forming has emerged as a pivotal technique, gaining traction among industry professionals for its efficiency and precision. Dr. James Whitaker, a renowned expert in advanced metalworking technologies, once stated, “Mastering metal flow forming is not just about skill; it’s about understanding the material’s behavior under pressure.” This insight encapsulates the essence of what it takes to excel in this specialized field.

As engineers and manufacturers increasingly turn to metal flow forming to create superior components with enhanced mechanical properties, it becomes imperative to grasp the fundamental principles and practices that underpin this technique. Understanding the intricacies of metal flow forming not only aids in optimizing production processes but also contributes to innovation in product design and application. In this guide, we will explore ten essential tips that will equip professionals with the knowledge needed to master metal flow forming techniques, ensuring they remain competitive in a demanding industry.

Table of Contents

[Hide]

Understanding the Basics of Metal Flow Forming Techniques

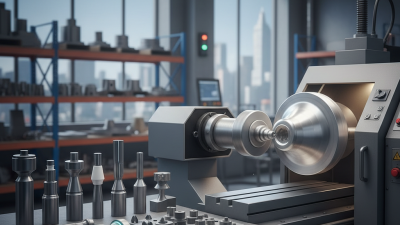

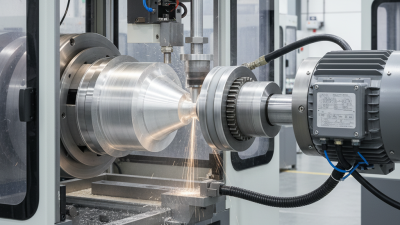

Metal flow forming is a sophisticated manufacturing technique that involves the precise shaping of metal through a series of controlled processes. Understanding the basics of this method is essential for anyone looking to master it. At its core, flow forming utilizes the principles of deformation and flow, allowing metal to be reshaped without significant material loss. The process begins with a pre-formed metal blank, which is mechanically stressed using specialized equipment. This stress causes the material to flow and stretch into the desired shape, making it an efficient alternative to traditional machining.

When engaging in metal flow forming, several factors play a crucial role in the quality of the finished product. The temperature of the metal, the speed of the forming process, and the specific geometry of the tooling all contribute to the final outcome. Understanding these parameters is vital, as they can significantly affect the metal's mechanical properties and dimensional accuracy. Furthermore, mastering flow forming techniques involves a steep learning curve, where practice and refinement of skills come into play. By prioritizing these foundational aspects, individuals can enhance their proficiency in this versatile and cost-effective manufacturing method.

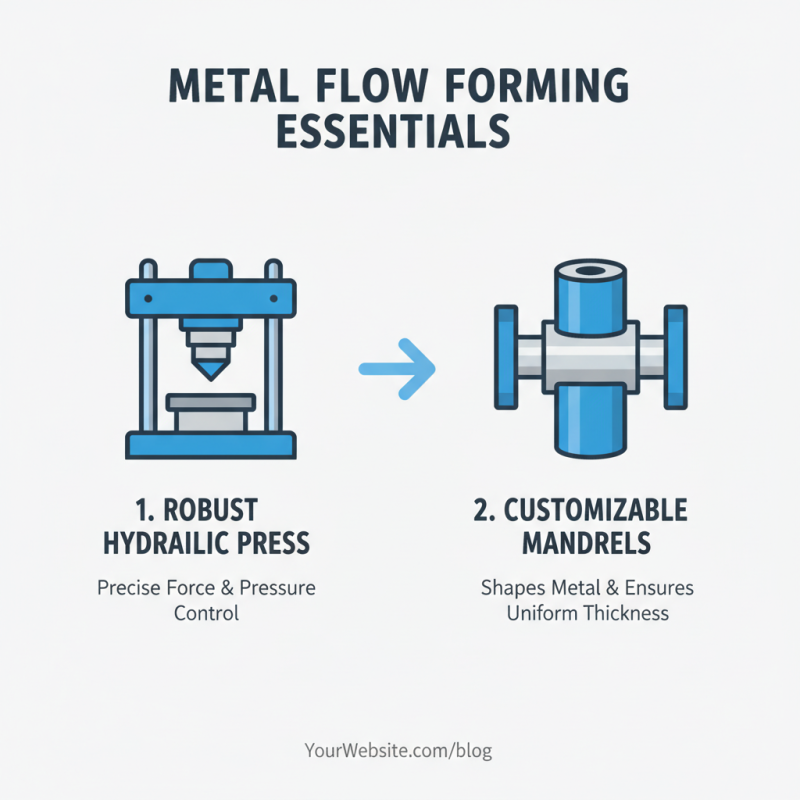

Key Tools and Equipment Needed for Metal Flow Forming

When venturing into the realm of metal flow forming, having the right tools and equipment is paramount. Firstly, a robust hydraulic press is essential for exerting the necessary force to shape metal effectively. This press should be capable of providing precise pressure control, allowing for consistent results across different projects. Alongside the hydraulic press, mandrels are critical as they shape the metal while ensuring uniform thickness and avoiding defects. These mandrels can be customized to fit the specific profiles required for various applications.

In addition to presses and mandrels, the use of high-quality tooling, such as dies and punches, cannot be overlooked. Dies facilitate repetitive and accurate shaping of the metal, while punches can create specific features or details in the forming process. Furthermore, heating systems may be necessary for certain materials that require elevated temperatures to achieve optimal malleability before the forming operation begins. By investing in these key tools and equipment, practitioners can significantly enhance their metal flow forming capabilities, leading to superior quality and efficiency in their manufacturing processes.

Step-by-Step Process of Metal Flow Forming

Metal flow forming is a sophisticated manufacturing technique that produces components with high precision and superior material properties. To master this process, it's essential to understand its step-by-step progression, ensuring each phase is executed with care and precision.

The first step in metal flow forming involves preparing the appropriate material, which requires selecting the correct metal type and testing it for quality. After ensuring the material meets the necessary standards, the next phase is to create the initial blank. It's crucial to maintain specific dimensions and tolerances during this stage, as they will impact the final product.

One tip to consider during the forming process is to monitor the temperature of the material closely. An optimal temperature can significantly influence the flow characteristics of the metal, enhancing its workability. Additionally, it's advisable to implement a controlled environment to reduce the risk of contamination, which can adversely affect the forming process. Ultimately, attention to detail at each step ensures a successful outcome in metal flow forming techniques.

10 Essential Tips for Mastering Metal Flow Forming Techniques

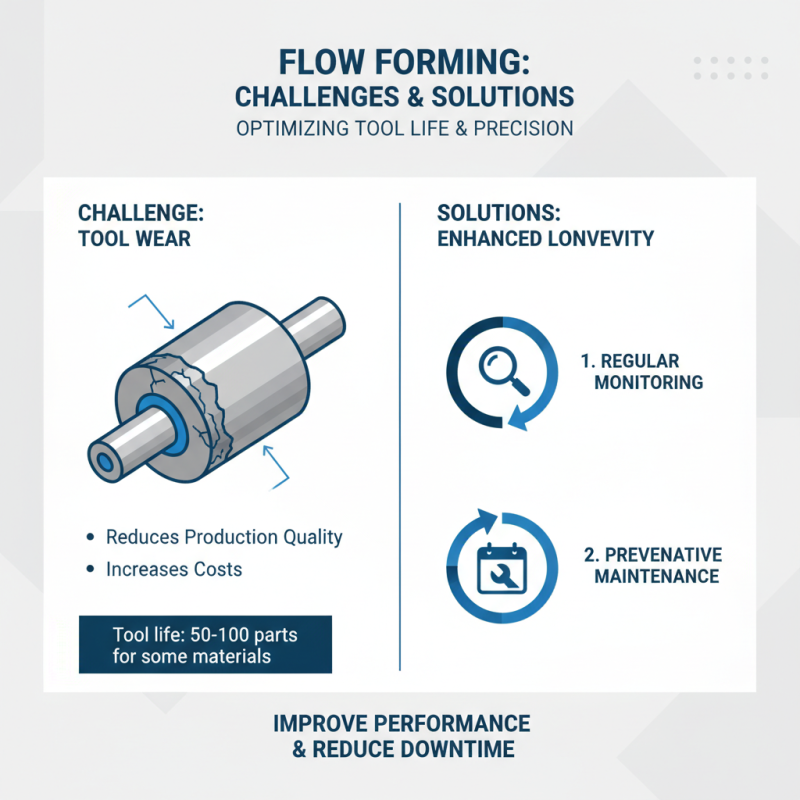

Common Challenges and Solutions in Flow Forming

Flow forming is a sophisticated manufacturing process known for its efficiency and precision, but it comes with its own set of challenges. One of the most common issues encountered is tool wear, which can significantly impact production quality and costs. According to recent industry reports, the tool life in flow forming can be as low as 50-100 parts for some materials. To combat this challenge, regular monitoring of tool conditions and implementing a preventive maintenance schedule can greatly enhance longevity and performance.

Another frequent hurdle is inconsistent material flow, which may lead to defects such as cracks or uneven thickness. Achieving uniform flow requires precise control of variables such as temperature and pressure. Studies show that optimizing these parameters can increase product consistency by up to 30%. Operators are advised to invest in training programs that emphasize the importance of machine calibration and environmental controls to mitigate these issues effectively.

To facilitate mastery in flow forming, one essential tip is to always conduct thorough material tests before production. Understanding the mechanical properties of the input material can help in determining the optimal forming conditions. Another crucial strategy is to collaborate with engineers to design parts that minimize stress concentrations, ultimately leading to a smoother manufacturing process. Embracing these tips can empower manufacturers to navigate common challenges and achieve excellence in flow forming techniques.

Best Practices for Quality Control in Metal Flow Forming Techniques

Quality control in metal flow forming techniques is critical to ensure the integrity and performance of the final products. According to a report by the International Journal of Advanced Manufacturing Technology, effective quality control measures can increase the production yield by up to 25%. This increase is largely due to the reduction of defects during the forming process, which can be mitigated through thorough monitoring and refining of parameters such as temperature, pressure, and material properties. A well-structured quality control system allows manufacturers to identify potential issues early in the production cycle, minimizing waste and improving efficiency.

To maintain high-quality standards in metal flow forming, it is essential to adopt best practices such as regular calibration of machinery and real-time monitoring of the forming process. Implementing statistical process control (SPC) techniques can provide insights into variations in production that may affect quality. A study from the American Society of Mechanical Engineers highlighted that facilities employing SPC techniques saw a reduction in defects by nearly 40%, showcasing the importance of data-driven decision-making. Additionally, training personnel on the significance of quality assurance can greatly enhance the overall process, as knowledgeable operators are better equipped to detect anomalies and enforce quality guidelines effectively.

By incorporating these quality control best practices, metal flow forming operations can significantly boost their reliability and output, positioning themselves for success in a competitive marketplace.

10 Essential Tips for Mastering Metal Flow Forming Techniques

| Tip Number | Tip Description | Benefits | Common Issues |

|---|---|---|---|

| 1 | Select the Right Material | Improved durability and formability | Material not suited for forming |

| 2 | Optimize Temperature Settings | Enhanced ductility | Risk of material cracking |

| 3 | Maintain Equipment Regularly | Consistent quality output | Increased downtime |

| 4 | Use Proper Lubrication | Reduced tool wear | Inconsistent forming results |

| 5 | Monitor Pressure Levels | Optimal forming conditions | Overloading equipment |

| 6 | Train Operators Effectively | Higher efficiency and quality | Operator errors |

| 7 | Implement Quality Control Checks | Early detection of defects | Overlooked quality issues |

| 8 | Experiment with Tooling Designs | Better production capabilities | Limited product range |

| 9 | Evaluate Production Processes | Identify inefficiencies | Persisting outdated methods |

| 10 | Stay Updated with Industry Trends | Competitive advantage | Outdated practices |

Related Posts

-

Why Choose Metal Forming Inc for Your Manufacturing Needs

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

What is Aluminium Spinning Machine and How Does it Work