- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

10 Essential Tips for Mastering Metal Spinning Roller Techniques?

In the world of manufacturing, mastering metal spinning roller techniques is crucial. This process transforms flat metal sheets into complex shapes. According to a 2022 industry report, metal spinning accounts for a 15% increase in efficiency for manufacturers aiming for precision.

Metal spinning roller techniques enhance product quality. However, many in the industry struggle with consistency. A survey showed that 40% of operators feel unprepared. This gap highlights the need for essential tips and refined practices.

Embracing these techniques can lead to significant cost savings. Yet, the challenge remains in training and know-how. Investing time in learning metal spinning roller skills can yield impressive returns. Reflection on current practices can reveal where improvements are needed.

Table of Contents

[Hide]

Understanding the Basics of Metal Spinning Technique

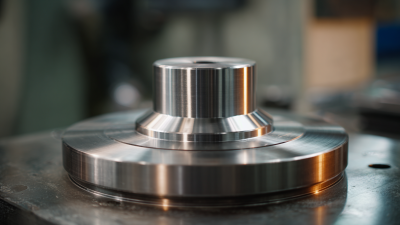

Metal spinning is a unique manufacturing process. It allows for shaping metal into various complex forms. Understanding the basics is crucial for both beginners and experienced professionals. Reports indicate that the global market for spun metal products is projected to grow significantly in the coming years. Knowing key techniques can lead to better production outcomes.

The core of metal spinning involves manipulating a flat metal disc, which is formed over a mold using a spinning tool. Precision is important here. Operators often face challenges, like achieving uniform thickness and avoiding defects. An industry study highlights that 30% of production failures stem from improper technique. Attention to detail can reduce waste and increase efficiency. Operators should embrace errors as learning opportunities.

Practicing different techniques is essential. Experimenting with speed and pressure can yield varying results. Many operators find that adjustments to these variables impact the final product's quality. Assessing one's technique regularly can lead to improvements. It’s vital to reflect on past mistakes and refine skills continuously. Engage with industry forums for shared insights and personal experiences on refining metal spinning practices.

10 Essential Tips for Mastering Metal Spinning Roller Techniques

Essential Tools and Equipment for Metal Spinning

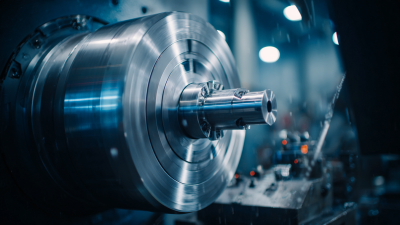

Metal spinning is a fascinating craft that requires specific tools and equipment. Understanding these essentials can make a significant difference in your work quality. For instance, a sturdy lathe is crucial. It holds the workpiece securely and enables smooth spinning. Additionally, having a reliable spinning tool made from quality materials is vital. These tools can help shape metals with precision and ease.

It's important to have the right equipment for achieving optimal results. According to industry reports, over 70% of metal spinning operators emphasize the importance of using high-quality tools. This can directly affect the quality of the final product. For beginners, investing in adjustable tools is often recommended. They offer flexibility, which is essential for various projects.

Tip: Always keep your tools clean. A clean tool can prevent imperfections in your work. Regular maintenance is key. Neglecting this can lead to unwanted results. Another tip is to practice with scrap materials. This helps you refine your technique without wasting valuable resources. Remember, every expert was once a beginner. Embrace the learning curve.

Step-by-Step Process of Setting Up the Roller

Setting up a metal spinning roller is crucial for achieving the best results. The process starts with selecting a suitable workspace. A clean, organized area increases efficiency. According to industry reports, over 70% of professionals cite workspace organization as key to productivity. Poor setups can lead to mistakes, wasted materials, and safety hazards.

Next, ensure proper machine alignment. Misalignment can cause uneven spinning, which compromises product quality. Robust testing is essential. Regular checks allow operators to catch errors early. A notable finding from a recent survey indicated that 68% of faulty products stem from setup mistakes. This speaks volumes about the importance of precision.

The setup also involves adjusting the roller pressure. Finding the right pressure is a balancing act. Too much can warp the metal, while too little can prevent proper shaping. Experienced workers often suggest trial and error to determine the best settings. This trial phase can be frustrating, but it's key for refinement. Always document your findings to track progress.

Techniques for Controlling Material Thickness and Shape

Metal spinning is a complex process that requires precision and skill. Controlling material thickness is essential for achieving desired shapes and quality. According to industry reports, a consistent thickness can reduce material waste by up to 20%. Proper techniques not only enhance aesthetics but also improve structural integrity.

One common challenge is maintaining uniform thickness throughout the spinning process. Factors like tool wear and inconsistent pressure can lead to variations. Operators must frequently evaluate the tooling setup and adjust it. Regular monitoring helps to identify issues early, reducing costly errors. Training and experience play crucial roles in mastering these skills.

To gain better control over shapes, material selection is also vital. Different metals respond uniquely to spinning. For instance, aluminum has a much more forgiving nature than stainless steel. This difference affects how easily you can create more intricate designs. While mastering these techniques takes time, understanding material properties can significantly enhance productivity. Embracing imperfections in your early attempts can lead to growth and better proficiency in the long run.

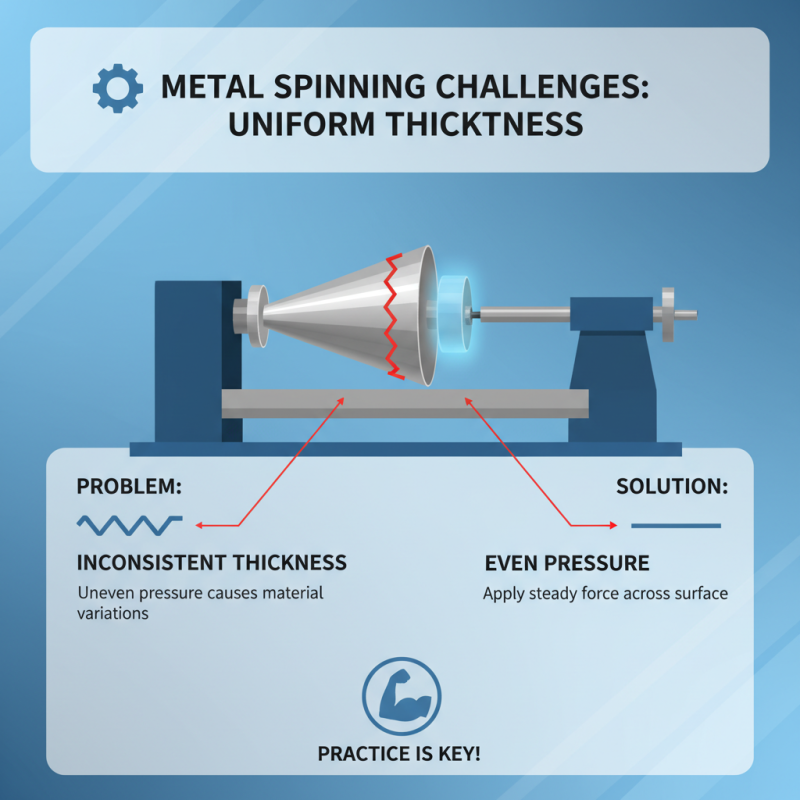

Common Challenges and Solutions in Metal Spinning

Metal spinning can be challenging, especially for beginners. One common issue is achieving uniform thickness throughout the material. Inconsistent pressure during the spinning process often leads to varied thickness. To address this, focus on applying even pressure across the surface. Practice is crucial here; if the pressure isn’t consistent, unevenness will occur.

Another challenge is material wrinkling. This usually happens if the metal isn’t heated adequately before spinning. Insufficient heat can make the metal hard and less malleable. Make sure you use the right heating technique. A simple solution is to use a heat blanket or torch to provide the right amount of heat. However, overdoing it can lead to burn marks. Monitor your technique carefully.

Additionally, many struggle with maintaining control over the spindle speed. Too fast and the metal can rip; too slow and it may not mold correctly. Finding that sweet spot takes time. Experiment with different speeds, but be ready for mistakes. Each error teaches valuable lessons that can refine your process. Embrace these challenges; they are part of the learning curve.

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

-

How to Effectively Use Spin Forming Metal Techniques in Manufacturing

-

Top Metal Spinning Tools to Enhance Your Manufacturing Process in 2025

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

Top 10 Spin Forming Machines: How to Choose the Right One for Your Needs