- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top 10 Factors to Consider When Choosing a Machine Shop

Choosing the right machine shop is crucial for successful projects. In an industry where precision and quality matter, the choice can significantly affect outcomes. According to the American Society of Mechanical Engineers, 70% of manufacturing issues stem from inadequate supplier selection. This highlights the importance of carefully evaluating machine shops before making a decision.

Factors like equipment capabilities, turnaround time, and workforce expertise all play a role. Reports show that shops with advanced CNC machinery can enhance production efficiency by up to 30%. Yet, not all shops invest equally in technology. It's essential to assess their technological edge. The industry also shows a growing emphasis on customer service and communication, with 65% of clients valuing responsiveness.

In the end, making a decision involves contemplation. What are your top priorities? Are you willing to compromise on certain aspects for better pricing? With a plethora of machine shops available, careful reflection on these factors can lead to more informed choices, ultimately impacting your project's success.

Table of Contents

[Hide]

Understanding the Machine Shop's Capabilities and Specializations

When choosing a machine shop, it’s crucial to understand their capabilities and specializations. A shop may excel in different areas, such as CNC machining, welding, or prototyping. Knowing these specialties can help you ensure they meet your precise needs. For example, if you need precision parts, a shop with extensive CNC experience would be ideal.

Evaluating a shop's past work is also important. Look for examples that align with your project requirements. Check if they have worked in your industry. This could affect their knowledge of materials and processes. A shop's equipment matters too. Outdated technology may limit their ability to deliver high-quality results.

Finally, consider their approach to customer service. Communication is key during a project. Make sure they listen to your concerns and provide feedback. A seamless dialogue can prevent issues down the road. Reflect on how their capabilities align with your vision. This will ensure you choose the right partner for your machining needs.

Top 10 Factors to Consider When Choosing a Machine Shop

| Factor | Description | Importance Level | Examples of Capabilities |

|---|---|---|---|

| Expertise and Specialization | Assess the shop's area of expertise and if it aligns with your project needs. | High | CNC Machining, Injection Molding |

| Equipment and Technology | Evaluate the quality and capabilities of the machines available. | High | 5-Axis Milling, Laser Cutting |

| Quality Control Processes | Look for certifications and procedures that ensure product quality. | High | ISO 9001, Six Sigma |

| Lead Times | Understand the shop's turnaround time for projects. | Medium | Standard vs. Rush Orders |

| Pricing Structure | Analyze pricing models and overall cost considerations. | Medium | Hourly Rate, Per-Project Pricing |

| Location | Consider proximity to reduce shipping costs and lead times. | Medium | Local vs. International |

| Previous Work and References | Check the shop's portfolio and client testimonials. | High | Past Projects, Case Studies |

| Customer Service and Support | Evaluate how responsive and helpful the staff are during inquiries. | Medium | Communication Channels, Responsiveness |

| Sustainability Practices | Look for environmentally friendly practices and materials used. | Low | Recycling Programs, Energy Efficient Machines |

Evaluating the Quality Control Processes and Standards Implemented

When selecting a machine shop, quality control processes are crucial. A robust quality control system ensures the final product meets specifications. Look for shops that perform regular inspections and testing. They should also track defects meticulously. This helps identify any recurring issues.

Standards are equally important. ISO certifications can indicate a commitment to maintaining quality. However, some shops may flaunt certifications without adhering to actual practices. Visit their facilities if possible. Observe their operations and ask questions. Check how they handle non-conformities. Transparency in these processes reflects a shop's reliability.

It’s essential to remember that not all machine shops have the same level of commitment to quality. Some might have impressive processes on paper but fail in real-world applications. This discrepancy can lead to delays and frustrations. Consider feedback from previous clients. Sometimes, firsthand reviews can reveal underlying problems that a glossy brochure cannot.

Top 10 Factors to Consider When Choosing a Machine Shop

Assessing the Availability of Advanced Machinery and Technology

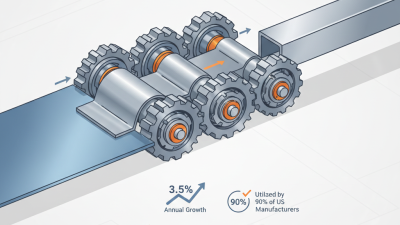

When choosing a machine shop, advanced machinery and technology are crucial. Access to state-of-the-art equipment can greatly enhance production quality. A recent report indicates that over 70% of manufacturers prioritize advanced technology in their production processes. Shops equipped with high-precision CNC machines and automated systems show improved efficiency. These advancements can reduce lead times by up to 30%.

However, not all shops can keep up with technological advancements. Limited budgets may force some to rely on outdated machinery. This can lead to inconsistencies in product quality. While some shops may offer competitive pricing, it often comes at the expense of technological capabilities. It's essential to assess whether the shop continuously invests in new technologies.

Another important factor is the training of staff to use advanced equipment. A 2022 survey revealed that 60% of manufacturers struggle with workforce training in new machinery. Without skilled technicians, even the best equipment may not be fully utilized. Therefore, evaluating both technology and human resources is vital when selecting a machine shop.

Considering Timeliness and Reliability in Project Turnaround

When choosing a machine shop, timeliness is a critical factor. Delays can cripple projects. A shop's ability to meet deadlines can save you time and money. Look for a facility that can provide a clear timeline. Ask about their average turnaround time. It’s important to get specifics, as vague answers may signal potential issues.

Reliability goes hand-in-hand with timeliness. A reliable machine shop consistently delivers quality work on schedule. It’s wise to check their past performance. Testimonials from previous clients can reveal their track record. A shop that misses deadlines may not prioritize your project. This can lead to frustration and setbacks.

Communication also plays a role. Ensure that the shop maintains open lines of dialogue throughout the process. You need updates on progress. A lack of interaction can raise concerns about your project’s status. If a shop struggles to provide timely information, consider it a red flag. Balancing timeliness and reliability is crucial for successful partnerships in manufacturing.

Reviewing Customer Service and Communication Practices of the Shop

When choosing a machine shop,

customer service and communication practices are vital.

A responsive shop can save time and reduce frustration. Notice how quickly they respond to inquiries.

A rapid reply often indicates a commitment to customer care.

Evaluate their communication style.

Is it clear and transparent?

Poor communication can lead to misunderstandings. If they fail to explain processes,

it might cause doubts about their capabilities.

A good shop will take the time to ensure you understand the project.

Tip:

Schedule a face-to-face meeting.

This allows you to gauge their professionalism.

Trust your instincts; if something feels off, it probably is.

Also, reflect on their willingness to listen.

Do they consider your ideas?

A shop that values your input is more likely to meet your needs.

Look for a balance between expertise and receptiveness.

Tip:

Ask for regular updates.

This keeps you in the loop and showcases their integrity.

A lack of communication can signal bigger issues ahead.

Always prioritize a shop that prioritizes you.

Related Posts

-

Why Choose Metal Forming Inc for Your Manufacturing Needs

-

10 Essential Tips for Mastering Metal Flow Forming Techniques

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

What is a Pipe Forming Machine and How Does It Work in the Industry

-

Understanding the Roll Forming Process: Benefits and Applications Explained