- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

What is Machining and Manufacturing Techniques Explained

Machining and manufacturing are cornerstones of modern industry. They shape raw materials into precision parts, impacting sectors from aerospace to automotive. According to a recent report by Grand View Research, the global machining market could reach $182 billion by 2027. This growth reflects increasing demand for high-quality precision components.

The continued evolution of machining and manufacturing techniques drives this sector forward. Advanced technology like CNC machining allows for faster, more accurate processes. However, many companies still struggle with inefficiencies. Over half of manufacturers report challenges in meeting production deadlines. This discrepancy highlights the need for continuous improvement in techniques.

As industries evolve, so must their approaches. Embracing automation and innovative materials can streamline processes. Yet, many organizations hesitate to adopt new methods. The fear of upfront costs and disruption often hold them back. Recognizing these barriers is crucial for future success in machining and manufacturing.

Table of Contents

[Hide]

Definition of Machining and Manufacturing Techniques

Machining and manufacturing techniques are essential processes in creating various products. Machining involves removing material from a workpiece to shape it into a desired form. This can be done using tools such as lathes, drills, and milling machines. Each tool has its unique purpose and effectiveness. However, the precision of machining often depends on the skill of the operator.

Manufacturing techniques encompass a broader range of processes. This includes not just machining, but also methods like casting, forging, and additive manufacturing. Each technique has its advantages and drawbacks. For instance, casting can produce complex shapes but sometimes lacks the precision machining offers. The choice of technique often influences the product's final quality.

It's crucial to consider possible imperfections in these processes. Machining can create tiny defects if not monitored closely. This is where attention to detail becomes vital. Each step in manufacturing requires careful planning and evaluation. As techniques evolve, embracing new methods can lead to innovation, but the risk of mistakes remains. Reflecting on these processes helps improve future outcomes.

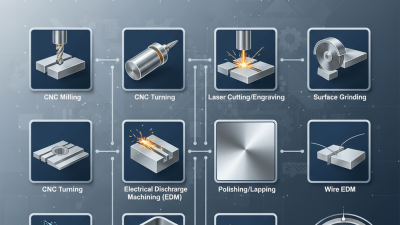

Types of Machining Processes and Their Applications

Machining processes are essential in manufacturing. They shape materials into specific forms. Understanding various techniques is crucial for efficient production.

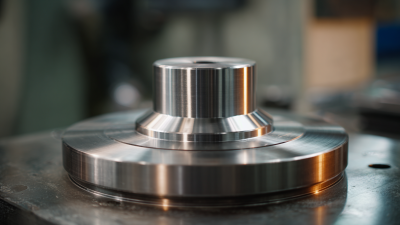

Turning is one common machining process. It involves rotating a material against a cutting tool. This creates cylindrical parts with precise dimensions. However, achieving perfect tolerances can be challenging. Small errors can lead to significant defects.

Milling is another widely used technique. It removes material from a workpiece using rotating cutters. This process is versatile and can create complex shapes. Yet, it requires a skilled operator to avoid mistakes. Drill bits and cutters must be selected carefully. Otherwise, the quality of the finished product may suffer.

Comparison Between Traditional and Modern Manufacturing Methods

When comparing traditional and modern manufacturing methods, clear differences emerge. Traditional techniques, like machining and casting, have defined manufacturing for decades. These methods often rely heavily on manual labor and skilled craftsmen. Products made this way can show unique imperfections and character. The use of simple tools and machines means there's a tangible connection between the artisan and the product. However, quality consistency can suffer, as human error plays a significant role.

In contrast, modern manufacturing techniques utilize advanced technology. Methods such as 3D printing and CNC machining enable precise creations. These processes often minimize human error, achieving consistency and excellence. Yet, they sometimes lack the soul found in traditional methods. The machinery can churn out parts rapidly, but the human touch is often missing. Additionally, setting up modern systems requires a significant investment. This can be a barrier for smaller manufacturers who wish to innovate. Each method has its strengths and weaknesses, needing careful consideration based on specific project goals.

Key Tools and Technologies Used in Machining

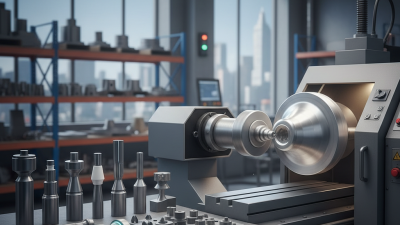

Machining is a crucial part of modern manufacturing. It involves various techniques to shape materials into desired forms. The key tools in this process include lathes, milling machines, and CNC (Computer Numerical Control) machines. CNC technology has dramatically changed machining. Reports indicate that the CNC machine market is projected to grow by 6.7% annually, highlighting its increasing importance.

Lathes are essential for rotationally symmetric parts. They create high precision shapes. However, they require skilled operators. Poor operation can lead to costly mistakes. Milling machines add complexity and versatility. They are used for flat surfaces and intricate designs. Despite improvements, some challenges remain, like tool wear and vibration issues.

Beyond machines, tools like drills and saws are critical. They help in various operations, but maintaining tool sharpness is necessary. Reports suggest that improper tool maintenance can reduce efficiency by up to 30%. This indicates a need for regular checks and training. The combination of technology and skilled labor is vital for successful machining processes.

What is Machining and Manufacturing Techniques Explained - Key Tools and Technologies Used in Machining

| Technique | Description | Key Tools | Common Materials |

|---|---|---|---|

| Turning | A machining process that removes material from a rotating workpiece using a cutting tool. | Lathes, CNC Turning Machines | Steel, Aluminum, Brass |

| Milling | A machining process that involves cutting and shaping material using rotating cutters. | Milling Machines, CNC Mills | Wood, Plastic, Metal |

| Drilling | A process for creating holes in materials using a rotating drill bit. | Drill Presses, CNC Drills | Wood, Metal, Concrete |

| Grinding | A process that uses an abrasive wheel to remove material from a workpiece surface. | Surface Grinders, CNC Grinders | Steel, Ceramics, Glass |

| Electrical Discharge Machining (EDM) | A machining method that removes material from a workpiece through electrical sparks. | EDM Machines, Wire Cut EDM | Metals, Hard Materials |

Future Trends in Machining and Manufacturing Techniques

The field of machining and manufacturing is evolving quickly. Advanced technologies are at the forefront. Automation is one key trend. Robots for repetitive tasks are becoming common, enhancing efficiency. However, this also raises questions about job displacement. Workers need to adapt to these changes.

Additive manufacturing is another exciting area. 3D printing allows for customized designs. Complex shapes can be created with ease. Still, materials used in 3D printing can be limited. Not all products are suitable for this method. Companies must evaluate sustainability and performance regularly.

Lastly, digital twin technology is gaining traction. This concept involves creating virtual replicas of physical machines. It aids in predictive maintenance. Yet, some firms struggle to implement this effectively. Integration can be complex, requiring significant resources. Continuous learning and adjustment are essential for future success in machining and manufacturing.

Machining and Manufacturing Techniques Trends

This chart illustrates the projected growth in the adoption of various machining and manufacturing techniques over the next five years. The data highlights the increasing trend towards automation, 3D printing, and advanced CNC machining as industries evolve.

Related Posts

-

Top 10 Best Deep Drawing Steel Techniques for Superior Metal Forming

-

Top 10 Spin Forming Machines: How to Choose the Right One for Your Needs

-

Top 10 Machining Metal Techniques for Precision Manufacturing Success

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

Top 10 Factors to Consider When Choosing a Machine Shop

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects