- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

What is Metal Machining Equipment and How Does It Work?

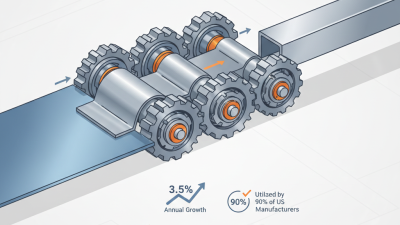

Metal machining equipment plays a crucial role in modern manufacturing. The global metal machining market was valued at approximately $80 billion in 2022. This value is expected to grow steadily. Innovations in this sector are vital for enhancing productivity and precision.

Machining processes involve various technologies such as turning, milling, and drilling. Each method utilizes specialized tools that shape metal parts. However, not all equipment is created equal. Some machinery may lack efficiency or precision. This inconsistency can lead to increased waste and costs for manufacturers.

Understanding how metal machining equipment works is essential for optimizing production. Many manufacturers still grapple with outdated systems. They may not fully utilize advanced technology. This gap poses a challenge, but also an opportunity for improvement. With the right equipment, companies can achieve significant gains in efficiency and output quality.

Table of Contents

[Hide]

Definition and Overview of Metal Machining Equipment

Metal machining equipment refers to tools and machines designed to shape metal parts. This process typically involves removing material from a solid block to achieve desired dimensions and specifications.

According to a 2022 market report, the global metal machining industry was valued at approximately $77 billion and is projected to grow significantly. Demand for precision components drives this trend, especially in industries like aerospace and automotive.

Various types of metal machining equipment exist, including lathes, mills, and grinders. Each type serves a distinct purpose. Lathes are used for creating cylindrical shapes, while milling machines provide flat surfaces and complex geometries. Grinders, on the other hand, refine surfaces to achieve tolerances of just a few micrometers. These tools utilize high-speed rotation and sharp cutting tools to achieve optimal results. However, even the most advanced machines face limitations. Issues like tool wear and vibration can affect precision and efficiency.

Proper setup and maintenance play a crucial role. Regular checks ensure that equipment operates smoothly. Neglecting these can lead to increased downtime and repair costs. Research shows that inefficient practices in metal machining can decrease productivity by as much as 20%. Focusing on continuous improvement can help mitigate these challenges.

Types of Metal Machining Processes and Their Applications

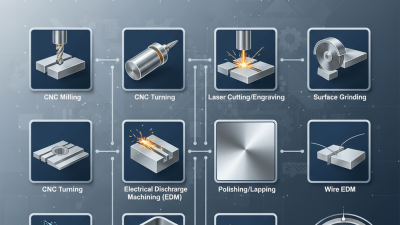

Metal machining processes play a crucial role in manufacturing. They help shape and cut metal into desired forms. Common types include turning, milling, and drilling. Each method has its own unique applications and characteristics.

Turning is often used to create cylindrical parts. The workpiece rotates while a cutting tool moves linearly. This process produces smooth surfaces, but may lack precision for complex shapes. Milling, on the other hand, involves a rotating cutter. It can create flat surfaces and intricate designs. However, its setup can be time-consuming. Drilling is typically the simplest method. It creates holes but requires careful selection of drill bits to avoid frequent replacements.

While these processes are effective, they are not without challenges. Material waste can occur during machining. Choosing the wrong process can lead to errors. Operators must pay attention to detail to avoid complications. Training and experience are important for achieving optimal results. Exploring new techniques and materials can also enhance machining efficiency.

Key Components and Mechanics of Metal Machining Equipment

Metal machining equipment plays a crucial role in manufacturing. Understanding its key components can help improve efficiency.

The main parts include cutting tools, workpieces, and fixtures. Cutting tools are designed to remove material from the workpiece. They can be made of various materials, such as high-speed steel or carbide. The choice of tool affects durability and precision.

Fixtures hold the workpiece securely. They ensure that the material does not move during machining. This stability is essential for achieving accurate measurements. Tips: always check that fixtures are properly aligned to avoid errors.

Machining processes vary widely. Turning, milling, and drilling are common methods. Each process requires specific parameters, such as speed and feed rate. Finding the right settings can be a trial-and-error process. Sometimes, it can take multiple adjustments to get it right. Tips: document your settings for future reference. Small changes can lead to big improvements.

Consider experimenting with different setups. It may reveal unexpected strengths or weaknesses. Continuous learning is key in this field. Embrace the imperfections and find ways to refine your process.

Impact of CNC Technology on Metal Machining Efficiency

CNC technology has revolutionized metal machining. It enhances efficiency and precision in manufacturing. This automated process reduces human error, leading to better quality products. CNC machines can create complex shapes within tight tolerances, something manual machining struggles with.

Tips: Regularly maintain your CNC equipment. A well-maintained machine operates efficiently. Check tool wear and replace them as needed. This simple step can noticeably improve output quality.

However, there are challenges. The initial investment for CNC machines can be high. Smaller businesses might struggle to justify this expense. Additionally, operator training is crucial. Without proper training, the potential of the machines can be underutilized.

Tips: Invest in continuous training for your team. Encourage learning and adaptability. It’s vital to keep up with technological advancements. Ultimately, better-trained operators will make a significant difference in efficiency.

What is Metal Machining Equipment and How Does It Work? - Impact of CNC Technology on Metal Machining Efficiency

| Machining Equipment | Type | CNC Technology Impact | Efficiency Gain (%) |

|---|---|---|---|

| Lathe | Turning | High precision and repeatability | 30% |

| Milling Machine | Milling | Reduced setup time and increased speed | 40% |

| Laser Cutter | Cutting | Complex shapes and rapid cutting speed | 50% |

| Water Jet Cutter | Cutting | No heat-affected zone, suitable for brittle materials | 35% |

| EDM Machine | Electrical Discharge Machining | High precision for hard materials | 25% |

Safety Standards and Best Practices in Metal Machining Operations

Safety is crucial in metal machining operations. Workers must wear appropriate personal protective equipment (PPE) such as goggles, gloves, and hearing protection. These safeguards help prevent injuries from flying debris, loud machinery, and sharp tools.

It is essential to conduct regular training sessions to keep safety practices fresh in employees' minds. However, many facilities overlook this, leading to increased risks.

Proper machine maintenance is another key aspect of safety. Neglected equipment may malfunction, causing accidents. Operators should regularly check for worn-out parts and ensure cutting tools are sharp. Wearing out tools can lead to unexpected slips, which can be dangerous. Often, workers may rush, thinking they can save time. This mindset can have serious consequences.

Additionally, maintaining a clean work environment is vital. Clutter can lead to trips and falls, causing injuries. Ensure that all tools are stored properly when not in use. Liquid spills should be cleaned immediately to prevent slips. Despite understanding these guidelines, many still ignore the basics. A culture of safety needs constant reinforcement to become a norm in machining operations.

Related Posts

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

Top 10 Spin Forming Machines: How to Choose the Right One for Your Needs

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

10 Essential Tips for Mastering Metal Flow Forming Techniques

-

Understanding the Roll Forming Process: Benefits and Applications Explained

-

Top 10 Machining Metal Techniques for Precision Manufacturing Success