- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

What is Metal Machining and How Does it Impact Manufacturing Processes

Metal machining is a crucial process in modern manufacturing that shapes and finishes metal components to precise specifications. According to Dr. Emily Rossi, a leading expert in the field of metal machining, "The accuracy and efficiency of machining processes are foundational to the quality of the final product." This statement highlights the significant role that metal machining plays in not only enhancing product performance but also ensuring that manufacturing operations remain competitive.

As industries evolve and demand for customized solutions increases, the impact of metal machining on manufacturing processes becomes even more pronounced. Advanced machining techniques, such as CNC machining, have revolutionized the way manufacturers approach production, allowing for higher precision, reduced lead times, and the ability to handle complex geometries. With the ability to produce intricate parts with minimal human intervention, metal machining is not just a method but a pivotal element that shapes the future of manufacturing.

In this discussion, we will explore the various facets of metal machining, its influence on production efficiency, and the innovations that are driving success in this industry. Understanding these elements is vital for professionals seeking to enhance their manufacturing capabilities and optimize their operational workflows.

Table of Contents

[Hide]

Introduction to Metal Machining: Definition and Overview

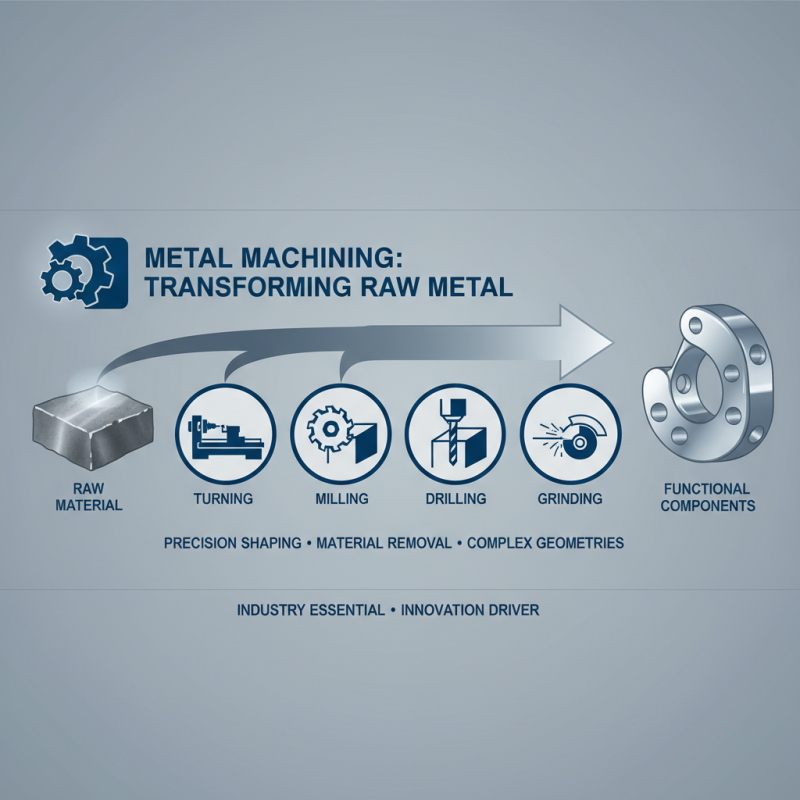

Metal machining is a fundamental process in the manufacturing industry, defining how raw metal materials are transformed into functional components. At its core, metal machining involves the removal of material from a workpiece to achieve desired shapes and sizes, using various cutting tools and techniques. This process includes methods such as turning, milling, drilling, and grinding, each serving a specific purpose in the production cycle. The precision involved in machining enables manufacturers to create intricate designs and complex geometries that are crucial for the performance of various products.

The impact of metal machining on manufacturing processes is significant, as it enhances both efficiency and accuracy in production. By employing advanced machining techniques, manufacturers can reduce waste, optimize material utilization, and shorten lead times. Furthermore, improvements in machining technology, such as computer numerical control (CNC), have allowed for greater automation and consistency, resulting in higher quality outputs. As industries continue to evolve with innovative materials and design requirements, the role of metal machining becomes increasingly vital, influencing not only how products are made but also their overall performance and dependability in the marketplace.

The Different Types of Metal Machining Processes Explained

Metal machining is an essential process in manufacturing, involving the removal of material from a workpiece to achieve desired shapes, dimensions, and surface finishes. There are various types of metal machining processes, each with specific applications and benefits. The primary methods include turning, milling, drilling, and grinding. According to a report by the Market Research Future, the global metal machining market is projected to exhibit a CAGR of 6.15% from 2023 to 2030, highlighting its significance in industrial production.

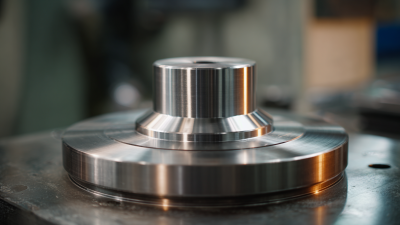

Turning is one of the most versatile machining processes, typically used for creating cylindrical parts. It involves rotating the workpiece against a cutting tool. Recent studies indicate that turning operations can achieve tolerances of ±0.005 mm, making them crucial for high-precision applications in sectors such as aerospace and automotive.

On the other hand, milling, which utilizes a rotating cutter to remove material from a stationary workpiece, is favored for producing complex geometries and tight tolerances. The demand for CNC milling machines has surged in recent years, with the market anticipated to reach around $12 billion by 2025, fueled by advancements in technology and increasing automation in manufacturing.

Drilling and grinding are also key processes in metal machining. Drilling is essential for creating holes and is particularly important in industries that require assembly of parts. Statistical analyses estimate that the drilling market will grow significantly, driven by increased demand in construction and manufacturing sectors.

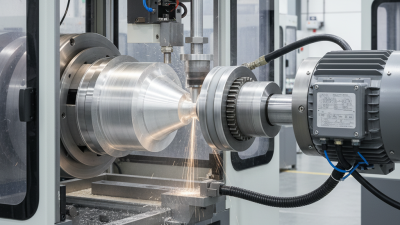

Grinding, which aims to achieve finer finishes and tighter tolerances, is critical in producing high-quality mechanical components. Recent data shows that the global grinding machinery market is expected to expand at a rate of 3.2% annually due to rising demands for precision-engineered products, underscoring the integral role machining processes play in modern manufacturing practices.

Key Tools and Equipment Used in Metal Machining

Metal machining is an essential aspect of modern manufacturing, characterized by the precise removal of material from a workpiece to achieve desired shapes, sizes, and finishes. The processes involved in metal machining utilize various key tools and equipment that play a critical role in ensuring accuracy and efficiency in production. According to the Association for Manufacturing Technology, the global machine tool market is projected to reach approximately $100 billion by 2025, reflecting the growing reliance on advanced machining techniques across various industries.

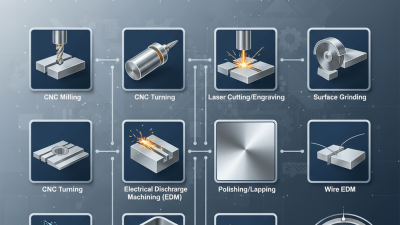

Among the most commonly used tools in metal machining are lathes, milling machines, and CNC (Computer Numerical Control) machines. Lathes are primarily used for shaping materials through rotation and cutting, making them essential for creating cylindrical components. Milling machines facilitate the removal of material through the rotational movement of cutting tools against the workpiece, allowing for intricate designs and surface features. CNC machines represent a significant advancement in machining technology, enabling automated control of machining tools through computer programming, which provides enhanced precision and consistency. The 2023 Metalworking Industry Report indicates that more than 65% of manufacturers have integrated CNC technology into their operations, citing increased productivity and reduced labor costs as key benefits.

In addition to these tools, the use of cutting fluids and lubricants is crucial in metal machining processes. These substances serve to reduce friction, dissipate heat, and improve the longevity of tools. As per data from the Precision Metalforming Association, the application of appropriate cutting fluids can improve tool life by up to 30%, further benefiting manufacturing efficiency. Overall, the right combination of tools and techniques in metal machining not only fosters product quality but also significantly impacts operational costs and manufacturing timelines.

Impact of Metal Machining on Manufacturing Processes

The Role of Metal Machining in Modern Manufacturing

Metal machining plays a critical role in modern manufacturing, serving as a foundational process in the production of various components across industries such as automotive, aerospace, and electronics. According to a report by Grand View Research, the global metal machining market is expected to reach USD 142.55 billion by 2025, driven by the increasing demand for precision-engineered products and advancements in machining technologies. This highlights the importance of metal machining as manufacturers strive for greater efficiency and precision in their operations.

The integration of advanced machining techniques, including computer numerical control (CNC) machining and additive manufacturing, has transformed metal machining practices. These technologies enable highly customized, reliable, and repeatable production processes, enhancing overall manufacturing effectiveness. For instance, CNC machining allows for the production of complex geometries with minimal human intervention, which significantly reduces the risk of errors and waste. According to the Association for Manufacturing Technology, companies implementing CNC systems can experience productivity improvements of 20-30%.

Tips: To optimize machining processes, manufacturers should invest in regular training for operators, ensuring they are adept at leveraging the latest technologies. Additionally, implementing preventive maintenance schedules for machinery can drastically reduce downtime and extend the lifespan of equipment. Engaging in continuous improvement methodologies, such as Lean manufacturing, can also help identify areas for efficiency gains, ultimately enhancing output quality and reducing production costs.

What is Metal Machining and How Does it Impact Manufacturing Processes

| Machining Process | Materials Used | Applications | Impact on Manufacturing |

|---|---|---|---|

| Turning | Steel, Aluminum, Brass | Automotive Parts, Shafts | High precision in circular parts, efficient for bulk production |

| Milling | Steel, Cast Iron, Plastics | Complex Shapes, Machine Components | Versatile for various shapes, enhancing design flexibility |

| Drilling | Steel, Aluminum, Composite Materials | Holes in Metal and Wood Products | Critical for assembly and component integration |

| Grinding | Steel, Hard Materials | Surface Finishing, Precision Parts | Improves surface finish and dimensional accuracy |

Impact of Metal Machining on Product Quality and Efficiency

Metal machining plays a crucial role in modern manufacturing, significantly influencing both product quality and operational efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, an estimated 70% of manufacturing costs are linked to machining processes. This highlights the importance of precision in machining, as even slight deviations can result in increased waste and rework. Implementing advanced machining techniques such as CNC (Computer Numerical Control) machining not only boosts accuracy but also reduces production time, enhancing overall efficiency. Data from the Society of Manufacturing Engineers suggests that companies employing CNC technology can achieve a 20-30% increase in productivity compared to traditional methods.

Moreover, the quality of precision components manufactured through effective machining is paramount, especially in industries such as aerospace and automotive, where safety and reliability are critical. A study from the American Society of Mechanical Engineers indicates that precision machining leads to a 15% improvement in product quality and reliability, emphasizing the impact of advanced machining on ensuring that parts meet stringent industry standards. By optimizing cutting speeds, feeds, and tooling, manufacturers can achieve superior finishes and tighter tolerances, ultimately enhancing customer satisfaction and reducing the cost of quality failures. Therefore, as manufacturing processes evolve, the strategic implementation of metal machining will continue to shape the landscape of industrial production.

Related Posts

-

Top 10 Machining Metal Techniques for Precision Manufacturing Success

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

What is Aluminium Spinning Machine and How Does it Work

-

10 Essential Tips for Mastering Metal Flow Forming Techniques

-

Why Choose Metal Forming Inc for Your Manufacturing Needs