- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

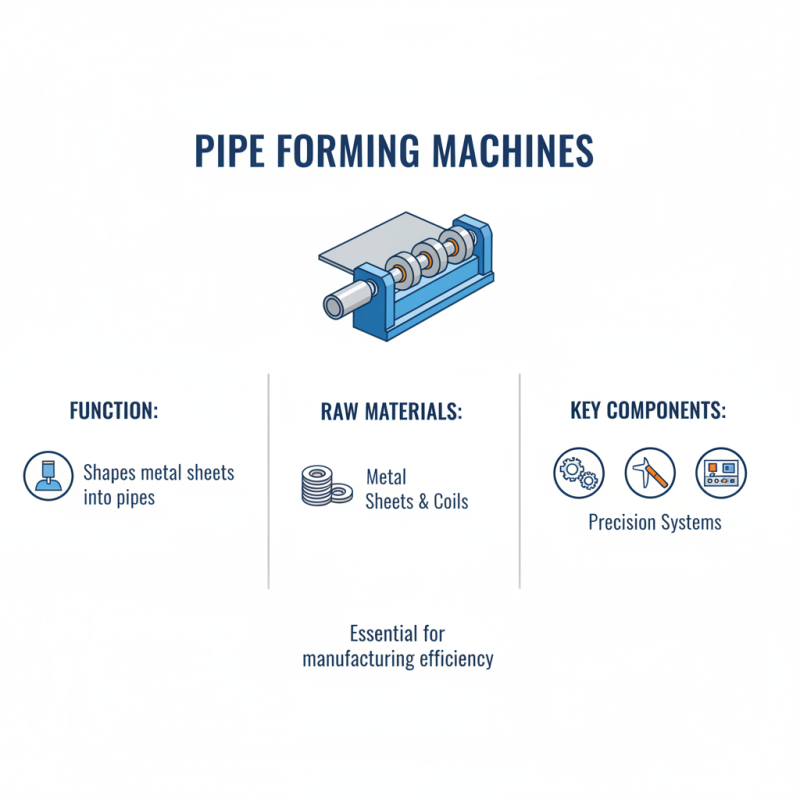

What is a Pipe Forming Machine and How Does It Work in the Industry

The pipe forming machine is an essential piece of equipment in the manufacturing industry, particularly for producing pipes used in various applications, ranging from construction to automotive industries. According to a recent report by the Global Pipe Manufacturing Association, the demand for pipe forming machines is expected to grow at a compound annual growth rate (CAGR) of 6.5% over the next five years, signifying a robust expansion in this sector. This growth can be attributed to the increasing need for high-quality pipelines that meet stringent industry standards and regulations.

Experts in the field have emphasized the critical role that these machines play in ensuring efficiency and precision in the pipe production process. John Smith, a leading engineer in the pipe manufacturing industry, stated, "A pipe forming machine not only enhances productivity but also significantly reduces material waste, which is vital in today’s competitive market." As manufacturers strive for greater sustainability and cost-effectiveness, the functionalities offered by pipe forming machines are becoming indispensable.

In this context, understanding the mechanisms and applications of pipe forming machines is crucial for industry stakeholders looking to optimize their operations and stay ahead in an increasingly challenging marketplace. This article explores the intricacies of pipe forming machines, their operational principles, and their impact on the industry landscape.

Table of Contents

[Hide]

What is a Pipe Forming Machine?

A pipe forming machine is a specialized piece of equipment designed to shape metal sheets into pipes or tubular structures. This process involves several techniques, including rolling, bending, and welding, to create seamless or welded pipes suitable for various applications in industries such as construction, automotive, and oil and gas. The machine typically features multiple rollers and dies that manipulate the metal into the desired curvature and diameter. By employing advanced control systems, modern pipe forming machines ensure precision and consistency in the production process.

In the industry, pipe forming machines play a crucial role in optimizing manufacturing efficiency and reducing production costs. They can handle a wide range of materials, including carbon steel, stainless steel, and aluminum, making them versatile for different sectors. The ability to produce pipes at high speeds while maintaining quality is vital, particularly in applications where structural integrity is paramount. With automation and computer numerical control (CNC) technology, these machines can quickly adapt to design changes, allowing manufacturers to respond effectively to market demands and enhance their competitiveness.

Key Components of Pipe Forming Machines

Pipe forming machines are essential tools in the manufacturing industry, designed to produce pipes of various shapes and sizes from metal sheets or coils. The key components of these machines work in unison to ensure precision and efficiency throughout the pipe-forming process.

One of the primary components of a pipe forming machine is the feeding mechanism, which controls the movement of the raw material into the machine. This mechanism ensures that the material is delivered uniformly and at the right speed, allowing for optimal processing. Following this is the forming section, where the material undergoes bending and shaping through the use of rollers or dies. These tools are crucial for achieving the desired pipe diameter and wall thickness, which are vital for the pipe's intended application.

Additionally, the machine is equipped with cutting systems that trim the formed pipes to the necessary lengths. This component must be highly accurate to maintain consistency in dimensions throughout production. Control systems also play a significant role, enabling operators to monitor and adjust parameters such as speed and temperature during the forming process. Together, these components facilitate a streamlined production flow, making pipe forming machines pivotal in various sectors, including construction, automotive, and energy industries.

The Pipe Forming Process Explained

The pipe forming process is a critical operation in various industries, enabling the production of pipes and tubes with precision and efficiency. This process typically begins with flat sheets or coils of metal, which are fed into a forming machine. The machine utilizes a series of rolls and dies to shape the metal into a cylindrical form. As the material passes through these rollers, it undergoes incremental bending, ensuring uniformity in diameter and wall thickness throughout the length of the pipe.

Once the metal is formed into a cylindrical shape, the edges are often joined together, which can involve techniques such as welding or mechanical fastening, depending on the requirements of the final product. Advanced pipe forming machines are equipped with sophisticated controls that allow for real-time monitoring and adjustments, ensuring that the pipes produced meet strict quality standards. The high degree of automation in this process not only enhances production efficiency but also reduces waste, making it an integral part of modern manufacturing practices. This streamlined approach contributes to the consistent supply of pipes used in plumbing, construction, and energy sectors, illustrating the vital role that pipe forming machines play in industrial operations.

Applications of Pipe Forming Machines in Various Industries

Pipe forming machines are integral to various industries due to their ability to produce pipes with precision and efficiency. In the construction sector, these machines are used to manufacture pipes for plumbing, drainage systems, and HVAC applications. The precise fabrication of pipes ensures that they meet specific standards for durability and flow efficiency, which is crucial for the overall functionality of buildings and infrastructure.

In addition to the construction industry, pipe forming machines play a vital role in the automotive and aerospace sectors. These machines are employed to create exhaust systems, fuel lines, and structural components where lightweight and strong pipes are essential. The ability to form complex shapes and sizes allows manufacturers to optimize designs for performance and safety. Furthermore, in the oil and gas industry, these machines are used to produce pipes that withstand high pressures and corrosive environments, ensuring the safe and efficient transportation of resources.

Advantages of Using Pipe Forming Machines in Manufacturing

Pipe forming machines are becoming increasingly vital in manufacturing due to their efficiency and precision in producing high-quality pipes. One of the key advantages of these machines is their ability to increase productivity. According to a report by Allied Market Research, the global market for pipe forming machines is expected to grow at a CAGR of 5.8% from 2021 to 2027, driven by the rising demand for industrial piping solutions across various sectors. This increase in productivity allows manufacturers to meet larger orders in shorter timeframes, ultimately enhancing their competitive edge in the market.

In addition to productivity, pipe forming machines also ensure greater uniformity and quality in the products produced. Traditional methods of pipe manufacturing often lead to inconsistencies and high waste, whereas modern pipe forming technology utilizes advanced automation and precision engineering. The American Society of Mechanical Engineers (ASME) highlights that these advancements improve the tolerances of pipe dimensions significantly, reducing material waste by up to 20%. Furthermore, manufacturers utilizing these machines benefit from reduced labor costs, as the automation processes lower the need for extensive manual labor, allowing skilled workers to focus on more complex tasks that require human intervention.

What is a Pipe Forming Machine and How Does It Work in the Industry

| Parameter | Description | Advantages |

|---|---|---|

| Machine Type | Tube and Pipe Formers | High precision forming |

| Material | Steel, Aluminum, Copper | Versatility in material usage |

| Production Speed | Up to 100 meters per minute | Increased efficiency |

| Energy Consumption | Low power usage | Cost-effective operation |

| Application Areas | Automotive, Construction, HVAC | Broad industrial applicability |

| Automation Level | Fully automated configurations available | Reduction of manual labor |

Related Posts

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know

-

How to Effectively Use Spin Forming Metal Techniques in Manufacturing

-

Top 10 Spin Forming Machines: How to Choose the Right One for Your Needs

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

Why Choose Metal Forming Inc for Your Manufacturing Needs

-

Top 10 Machining Metal Techniques for Precision Manufacturing Success