- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top 10 Spin Forming Machines: How to Choose the Right One for Your Needs

In the world of manufacturing, the significance of selecting the right equipment cannot be overstated, especially when it comes to specialized machinery like the spin forming machine. Industry expert Sarah Mitchell, a leading figure in metalworking technology, emphasizes, "Choosing the right spin forming machine can make all the difference in achieving precision and efficiency in your production line." This insight reflects the crucial impact that these machines play in various applications, from automotive components to aerospace parts.

As industries continue to evolve and demand for precision engineering rises, understanding what to look for in a spin forming machine becomes essential. The range of options available today can be overwhelming, and each machine offers different capabilities tailored to specific needs. By considering factors such as material types, production volume, and desired outcomes, manufacturers can pinpoint the perfect machine that aligns with their operational goals.

Navigating this decision-making process requires not only understanding the technical specifications but also evaluating the long-term benefits of investing in a spin forming machine. From enhancing production efficiency to ensuring superior product quality, the right choice can lead to significant advancements in manufacturing processes. This article will explore the top ten spin forming machines available today, providing insights to help refine your selection process and optimize your production capabilities.

Table of Contents

[Hide]

Understanding Spin Forming Machines: A Comprehensive Overview

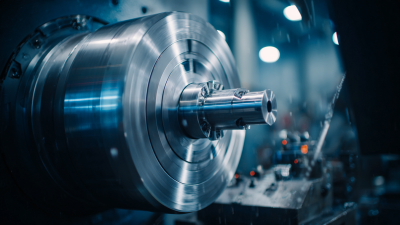

Spin forming machines represent a crucial technology in various manufacturing sectors, particularly in the production of cylindrical and conical shapes from metal. These machines utilize a process where a metal disc is rotated at high speed while being pressed against a mold, allowing for the material to conform to the desired shape. According to a recent report by Research and Markets, the global market for spin forming machines is projected to grow at a CAGR of approximately 5.7% from 2023 to 2030, driven by increased demand in industries such as aerospace and automotive.

Understanding the core functionalities and types of spin forming machines is essential for making an informed purchasing decision. Generally, they can be categorized into manual, semi-automatic, and fully automatic machines. Each type offers various levels of precision and automation, which can significantly influence production efficiency. For instance, fully automatic machines are ideal for large-scale operations requiring consistent quality, while manual machines may be suitable for smaller, customized projects. According to industry analysis, choosing the right machine involves assessing factors such as material compatibility, production volume, and the complexity of design. These elements play a vital role in ensuring that manufacturers can meet their operational needs without compromising on quality or efficiency.

Key Features to Consider When Selecting a Spin Forming Machine

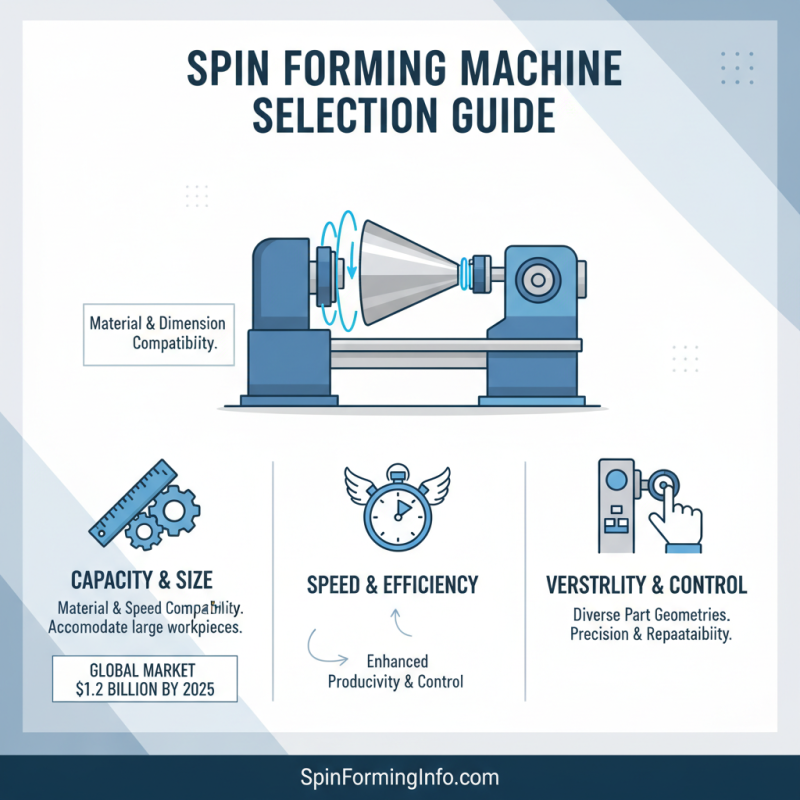

When selecting a spin forming machine, several key features should be taken into consideration to ensure it meets your specific production needs. First and foremost, assess the machine's capacity and size to determine if it can accommodate the materials and dimensions you work with. According to a recent industry report, the global market for spin forming machines is expected to reach $1.2 billion by 2025, highlighting the growing demand for versatile and efficient machines. Additionally, consider the machine's speed and efficiency; models that offer adjustable speed settings can enhance productivity and allow for better control over the forming process.

Another essential feature to focus on is the machine's construction quality and durability. A well-built spin forming machine can withstand the rigors of continuous production while providing consistent results over time. Look for machines with high-quality materials and robust design, as these can significantly reduce maintenance costs and downtime. It is also worthwhile to evaluate the availability of support and training from manufacturers, as knowledgeable assistance can impact the optimal use of the machine.

Tips: When choosing a spin forming machine, prioritize ones with user-friendly interfaces and automation capabilities. This can streamline operations and minimize the learning curve for your staff. Additionally, consider testing the machine's performance through demonstrations or reviews from other users. This first-hand feedback can provide invaluable insights into the machine's reliability and efficiency before making a purchase decision.

Evaluating Machine Size and Capacity for Your Specific Applications

When selecting a spin forming machine, evaluating the machine's size and capacity is crucial to ensure it meets your specific application needs. The size of the machine often dictates the maximum dimensions of the parts that can be produced. It’s essential to analyze the materials you will be working with, as heavier or thicker materials may require larger machines with higher power capabilities. Additionally, consider the workspace available in your facility, since accommodating a larger machine may necessitate redesigning the layout or investing in additional infrastructure.

Capacity is another key factor that plays a significant role in the machine's suitability for your operations. This includes not only the physical volume of material the machine can handle but also its production speed. If your applications demand high-volume production, a machine with a larger capacity and faster processing capabilities will be necessary to keep up with demand. Moreover, examining the machine's tooling options and the ability to interchange different tools can enhance its versatility, making it a better fit for varied applications in the long run. Ultimately, understanding these specifications will help you choose a spin forming machine that is ideally suited for your operational requirements.

Top 10 Spin Forming Machines: Capacity and Size Comparison

Comparing Material Compatibility and Process Efficiency

When choosing the right spin forming machine, material compatibility is a crucial factor to consider. Different materials, ranging from metals to plastics, exhibit varying properties that can affect the spinning process. For instance, ductile metals like aluminum and copper can be easily shaped into intricate designs, while harder materials such as steel may require more robust machinery and specific dies for successful forming. It's essential to assess the materials you plan to work with to ensure that the selected machine can handle their unique characteristics without compromising quality or efficiency.

Process efficiency is another key aspect in selecting a spin forming machine. This involves understanding the machine's performance in terms of speed, accuracy, and energy consumption. A machine that operates efficiently can significantly reduce production time while maintaining precision in the formed products. Furthermore, factors such as the machine's ability to minimize waste and its adaptability to different production volumes are vital in maximizing overall operational efficiency. Consequently, evaluating both material compatibility and process efficiency will help you make an informed decision, ensuring that the chosen spin forming machine meets your specific production needs effectively.

Budget Considerations: Cost vs. Value in Spin Forming Machinery

When selecting a spin forming machine, one of the most critical factors to consider is the balance between cost and value. While it might be tempting to go for the most affordable option, it's essential to evaluate what capabilities and features you are sacrificing at a lower price point. Cheap machines may come with limitations in precision, durability, and efficiency, which can result in higher operational costs over time. Therefore, understanding the specific needs of your projects is crucial to making a financially sound decision.

Investing in higher-quality spin forming equipment can yield better long-term results, even if the initial expense appears daunting. High-value machines often offer advanced technology, improved safety features, and superior support services, leading to reduced downtime and enhanced productivity. A well-chosen machine can not only enhance your production capabilities but also contribute to achieving better product quality, ensuring your operations remain competitive within the industry. Thus, weighing the cost against the potential value and return on investment should guide your choice in spin forming machinery.

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

Why Choose Metal Forming Inc for Your Manufacturing Needs

-

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

Understanding the Roll Forming Process: Benefits and Applications Explained

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry