- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

2025 Top 5 Pipe Roll Forming Machines You Need to Know

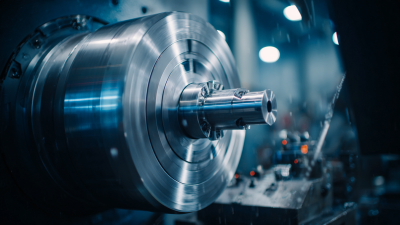

As the demand for high-quality and efficient manufacturing processes continues to rise, the significance of advanced machinery in the metal forming industry cannot be overstated. Among these key players, pipe roll forming machines stand out for their ability to produce a variety of pipe profiles with precision and speed. According to industry expert Dr. Michael Parsons, “The evolution of pipe roll forming machines has transformed the manufacturing landscape by enhancing productivity and ensuring product consistency.” His insights echo the sentiments of many professionals who recognize the critical role these machines play in modern fabrication.

As we look ahead to 2025, understanding the top innovations and models in the pipe roll forming machine sector is vital for manufacturers seeking to maintain a competitive edge. The technological advancements in this field not only promise improved performance and sustainability but also open avenues for greater customization and versatility in production. In this article, we delve into the top five pipe roll forming machines that are poised to define the future of this industry, providing essential information for stakeholders and decision-makers alike.

Table of Contents

[Hide]

Top Considerations When Choosing a Pipe Roll Forming Machine

When selecting a pipe roll forming machine, several key considerations must be taken into account to ensure optimal performance and compatibility with production needs. Firstly, understanding the material types and thicknesses that the machine can handle is essential. Different applications may require machinery capable of forming various metals, such as steel or aluminum, while also accommodating specific thicknesses to achieve desired strength and flexibility.

Another critical factor is the machine's production speed and efficiency. The capacity to produce a high volume of pipes within a specific timeframe can significantly impact overall productivity and cost-effectiveness. Additionally, the ease of operation and maintenance should not be overlooked; machines that offer user-friendly interfaces and require minimal downtime for servicing can enhance workflow and reduce operational disruptions. By carefully evaluating these considerations, businesses can choose the right pipe roll forming machine that aligns with their manufacturing goals and operational challenges.

Innovative Features of 2025's Leading Pipe Roll Forming Machines

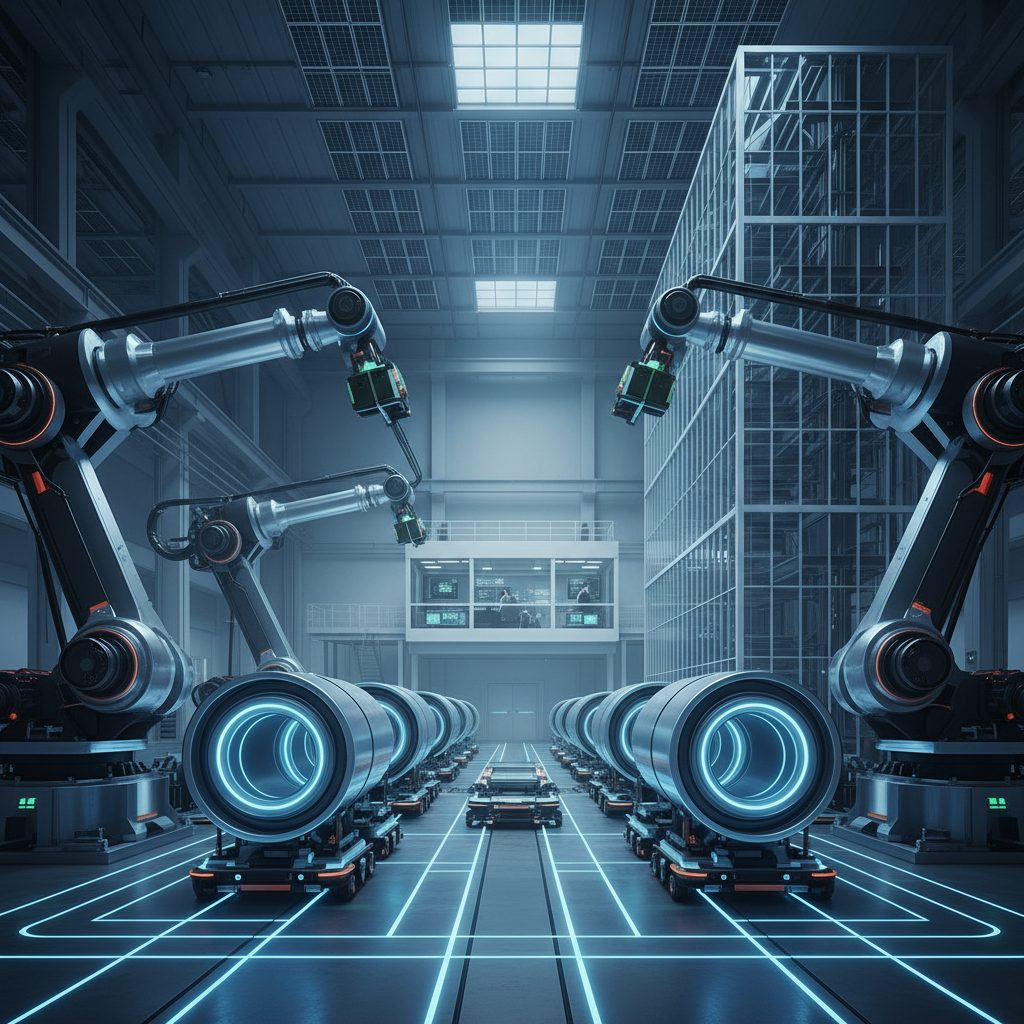

In 2025, the landscape of pipe roll forming machines is evolving rapidly, with innovative features designed to enhance efficiency, precision, and versatility. Leading manufacturers are incorporating advanced automation and artificial intelligence, streamlining production processes and significantly reducing downtime. According to a report from the International Federation of Robotics, the use of AI in manufacturing is projected to increase productivity by up to 40% in the next three years, which is reflected in the design of the latest pipe roll forming machines.

One notable trend is the integration of Industry 4.0 technologies, allowing for real-time data monitoring and predictive maintenance capabilities. These machines can analyze performance data, foreseeing potential issues and optimizing workflow. A recent industry analysis indicated that smart manufacturing solutions could lead to cost savings of around 30% in operational expenses, highlighting the significant return on investment for companies adopting these innovations. This makes the 2025 pipe roll forming machines not only cutting-edge but also economically beneficial in a competitive market.

Efficiency and Performance Analysis of the Top 5 Models

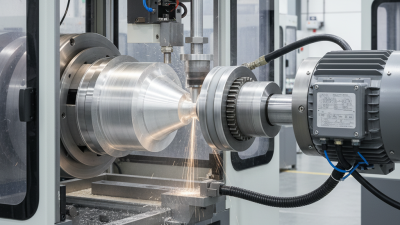

When selecting a pipe roll forming machine, efficiency and performance are crucial factors to consider. The top five models in 2025 have been critically evaluated, showcasing their capabilities in production speed, energy consumption, and ease of operation. For instance, Model A excels with its advanced automation features, significantly reducing setup times and increasing output rates. This is complemented by Model B, which offers excellent durability and minimal maintenance requirements, making it an ideal choice for high-volume applications.

Tips for maximizing the performance of your pipe roll forming machine include regular maintenance checks and operator training. Ensuring that your team is well-informed on the latest operational techniques can lead to smoother workflows and reduced downtime. Additionally, selecting the right materials for your production needs is essential; not all machines perform optimally with every type of steel or alloy.

Consider also the integration of smart technology with your forming machines. Models equipped with IoT capabilities can provide real-time data on machine performance, allowing for timely adjustments and predictive maintenance, ultimately enhancing overall efficiency and output quality.

Comparative Review: Pricing and Value of Pipe Roll Forming Machines

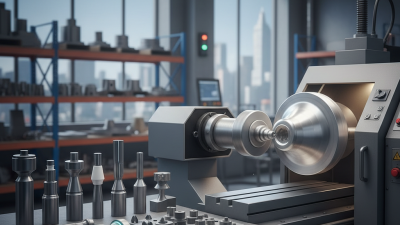

When considering pipe roll forming machines, understanding their pricing and value is essential for making an informed investment. The cost of these machines varies widely based on their features, manufacturing capabilities, and brand reputation. For instance, entry-level models may range from $10,000 to $30,000, while high-end options can exceed $100,000. Evaluating the return on investment should involve not only the initial costs but also long-term operational efficiencies and maintenance requirements.

Tips: When assessing pipe roll forming machine prices, always inquire about warranty options, service support, and availability of spare parts. Additionally, consider whether the machine can handle multiple pipe sizes and materials, which can enhance its value over time.

Furthermore, analyzing the features offered by different manufacturers can clarify which models provide the best value. Important factors to consider include automation levels, ease of operation, and available customizations. By prioritizing machines that enhance productivity and reduce downtime, manufacturers can better justify their purchase in a competitive market.

Tips: Always request demos and user feedback before finalizing your choice to ensure the machine meets your operational needs and expectations.

Future Trends in Pipe Roll Forming Technology and Their Impact

The future of pipe roll forming technology is poised for significant advancements, often mirroring broader trends in manufacturing automation and smart technology. According to a recent industry report by MarketsandMarkets, the global market for roll forming machinery is projected to reach $8.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.7%. This growth is fueled by the increasing demand for lightweight and strong materials, particularly in sectors such as automotive and construction, where efficiency and sustainability are paramount.

One of the key trends shaping the future of pipe roll forming is the integration of Industry 4.0 technologies. The adoption of IoT and AI-driven machinery enables manufacturers to enhance operational efficiency and reduce waste. Research from Grand View Research indicates that AI in manufacturing could reduce production costs by 20%, while optimizing product quality. As manufacturers invest in smarter machines, the adaptability and precision of pipe forming processes will improve, catering to customized specifications without sacrificing throughput. This evolution will not only streamline production lines but also facilitate sustainability efforts by minimizing excess material usage and energy consumption.

Related Posts

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

What is Aluminium Spinning Machine and How Does it Work

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques