- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top Forging Machines to Watch for in 2025 and Their Industry Impact

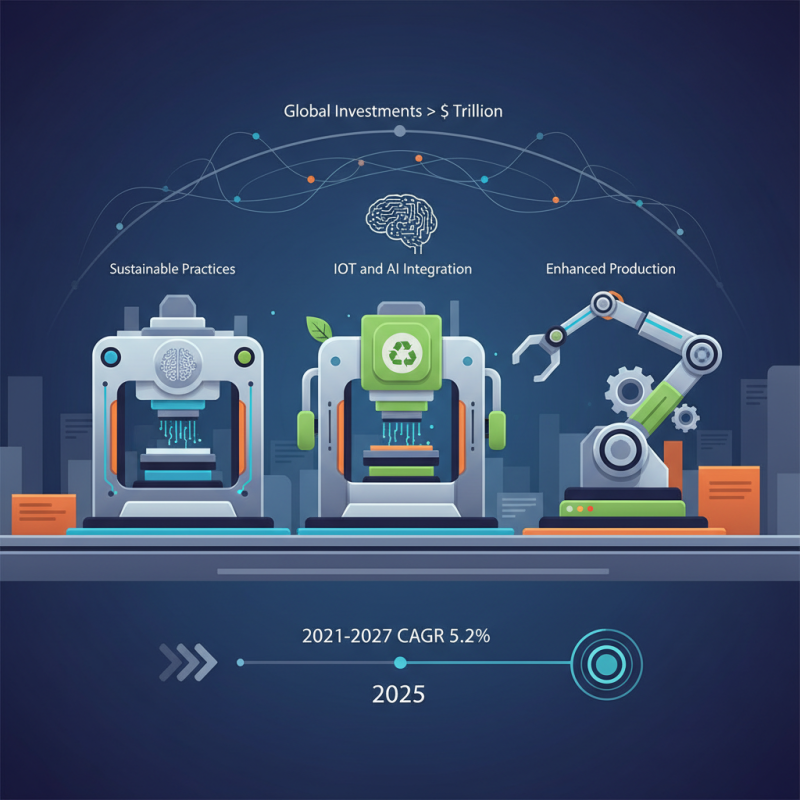

In the evolving landscape of manufacturing technology, the forging machine industry is poised for significant advancements by 2025. As global investments in manufacturing technologies are projected to exceed $1 trillion, the importance of high-efficiency forging machines cannot be overstated. According to a recent report by Market Research Future, the global forging machine market is expected to grow at a CAGR of 5.2% between 2021 and 2027, driven by increasing demand from sectors like automotive, aerospace, and heavy machinery.

Industry expert Dr. Emily Williams emphasizes the transformative role of forging machines in enhancing production efficiency and product quality. She stated, "The next generation of forging machines will not only streamline operations but also integrate advanced technologies like IoT and AI, paving the way for smart manufacturing." This evolution is not merely technological; it reflects a broader trend towards sustainable practices, where forging machines are becoming more energy-efficient and capable of producing less waste, thus contributing to industry sustainability goals.

As we look toward 2025, understanding the key innovations and the potential impact of these forging machines remains crucial for stakeholders. The shift towards automation and advanced manufacturing processes signifies a critical juncture in the industry, making it imperative for manufacturers to stay informed and adapt to emerging technologies that will shape the future of forging.

Table of Contents

[Hide]

Top Trends in Forging Technology Set for 2025

The forging industry is poised for significant advancements in 2025, driven by key trends in technology that are reshaping processes and enhancing efficiency. One major trend is the integration of IoT (Internet of Things) into forging machines, enabling real-time monitoring and optimization of production workflows. This connectivity offers manufacturers valuable data insights, allowing them to make informed decisions that lead to reduced downtime and improved quality control.

Another pivotal trend is the adoption of advanced materials and processes, such as additive manufacturing combined with traditional forging techniques. This approach not only optimizes material usage but also allows for the creation of intricate designs that were previously unattainable. As industries demand lighter and stronger components, embracing these innovative practices will be crucial for staying competitive.

Tips: As you explore these emerging trends, consider investing in training for your workforce to adapt to new technologies seamlessly. Moreover, establishing strategic partnerships with technology providers can enhance your capabilities and keep you ahead of the curve. Emphasizing sustainability by adopting eco-friendly practices will not only meet regulatory demands but also appeal to a growing market focused on environmental responsibility.

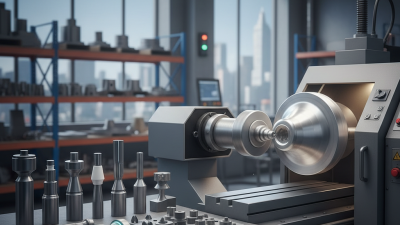

Key Characteristics of Leading Forging Machines in 2025

As the forging industry evolves, the characteristics of leading forging machines are becoming increasingly significant. In 2025, top forging machines will prioritize precision, efficiency, and adaptability. Advanced control systems will enable real-time monitoring and adjustments, ensuring that each forging process meets stringent quality standards. The integration of artificial intelligence will aid in predictive maintenance, allowing machines to self-optimize and reduce downtime significantly.

When selecting a forging machine, it's essential to consider the machine's energy efficiency. Opting for machines designed with reduced energy consumption not only lowers operational costs but also aligns with sustainability goals that are becoming a priority in manufacturing industries. Look for features like regenerative braking and energy recovery systems.

Another critical aspect is the versatility of the machines. The ability to easily switch between different manufacturing processes or materials can greatly enhance productivity. Machines that offer modular designs or quick-change tooling systems can adapt to various production demands without substantial reconfiguration time. This flexibility will be crucial as industries respond to fluctuating market needs in 2025 and beyond.

Impact of Automation and AI on Forging Machine Efficiency

The integration of automation and artificial intelligence (AI) into the forging industry is revolutionizing machine efficiency and productivity. These technologies are not merely trends but are becoming essential for manufacturers looking to enhance their operational capabilities. Automated forging machines equipped with AI can analyze data in real-time, adjusting parameters to optimize the forging process. This leads to reduced waste, improved product quality, and shorter cycle times. As a result, companies can meet increasing demands while minimizing costs, paving the way for more sustainable manufacturing practices.

Moreover, the adoption of smart technologies allows for unprecedented flexibility and adaptability in production lines. By utilizing machine learning algorithms, these forging machines can learn from past performance and make intelligent predictions about future production needs. This not only enhances scheduling and resource allocation but also reduces downtime through proactive maintenance. The impact of these advancements extends beyond mere efficiency gains; they are reshaping the workforce dynamics, as skilled labor is complemented by intelligent machines, creating new roles focused on machine oversight and advanced data analysis. As the forging industry continues to embrace these innovations, the potential for enhanced efficiency and productivity will drive significant changes in how products are made and delivered.

Environmental Considerations: Eco-Friendly Forging Machines

As the forging industry looks to the future, eco-friendly forging machines are set to play a crucial role in minimizing environmental impact. With growing awareness of sustainability, manufacturers are seeking ways to reduce energy consumption and greenhouse gas emissions. Innovations in technology, such as advanced hydraulic systems and energy-efficient motors, enable forging processes to operate at lower energy levels, contributing to a greener production model. Additionally, the integration of renewable energy sources into forging operations exemplifies a proactive approach to addressing climate change.

Furthermore, eco-friendly forging machines often incorporate materials and designs that promote recyclability and waste reduction. The implementation of closed-loop systems allows for the durable recycling of scrap material, significantly decreasing waste. As these machines are designed with sustainability in mind, they also utilize safer, less harmful lubricants and cooling agents, thereby reducing pollutants released into the environment. This focus not only helps in compliance with stringent environmental regulations but also enhances the brand image of manufacturers committed to sustainable practices, driving an industry-wide shift towards eco-conscious production methods.

Predicted Market Growth and Economic Influence of Forging Machines by 2025

The forging machine market is poised for significant growth by 2025, driven by advancements in manufacturing technology and increasing demand across various sectors. A recent report from Market Research Future indicates that the global forging market is expected to reach a valuation of approximately $90 billion by 2025, with a compound annual growth rate (CAGR) of around 5.6% from 2020 to 2025. This growth can be attributed to the rising integration of automation and digitalization in manufacturing processes, which enhances efficiency and reduces operational costs.

The economic influence of forging machines extends beyond mere production capabilities; it also plays a crucial role in job creation and industry evolution. As the automotive and aerospace industries continue to grow, the need for precision-engineered components increases, prompting the adoption of advanced forging technologies. According to a report from ResearchAndMarkets, the automotive sector alone is projected to account for over 40% of the forging market share by 2025, emphasizing the significance of forging machines in supporting this critical industry. Furthermore, the transition towards sustainable practices is driving innovations in forging techniques, making them more environmentally friendly while meeting stringent regulations. This shift is expected to bolster the market as industries seek to minimize their carbon footprint and embrace greener manufacturing solutions.

Related Posts

-

How to Choose the Best Metal Spinning Lathe Tools for Your Projects

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

2025 Top 5 Engineering Machinery Innovations Transforming the Industry

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

2025 Top 5 Pipe Roll Forming Machines You Need to Know

-

How to Use Flow Forming Steel for Maximum Strength and Durability