- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top 10 Machining Metal Techniques for Precision Manufacturing Success

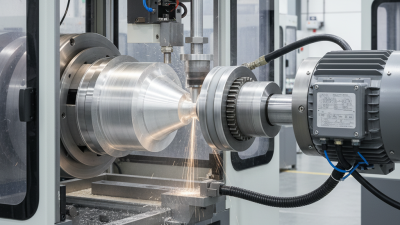

In the ever-evolving landscape of manufacturing, precision plays a crucial role in ensuring the success of various industries. Among the myriad of techniques available, machining metal stands out as a fundamental process that drives accuracy and quality in the production of intricate components. Mastering the art of machining metal not only enhances efficiency but also significantly impacts the final product's performance and durability.

This article delves into the top ten machining metal techniques that industry leaders leverage to achieve excellence in precision manufacturing. From advanced computer numerical control (CNC) methods to innovative surface finishing techniques, each process is designed to maximize precision while minimizing waste. Understanding and implementing these techniques can provide manufacturers with the competitive edge necessary to thrive in today's demanding market. As we explore these essential machining metal strategies, we will uncover insights that can facilitate better production outcomes and contribute to overall manufacturing success.

Table of Contents

[Hide]

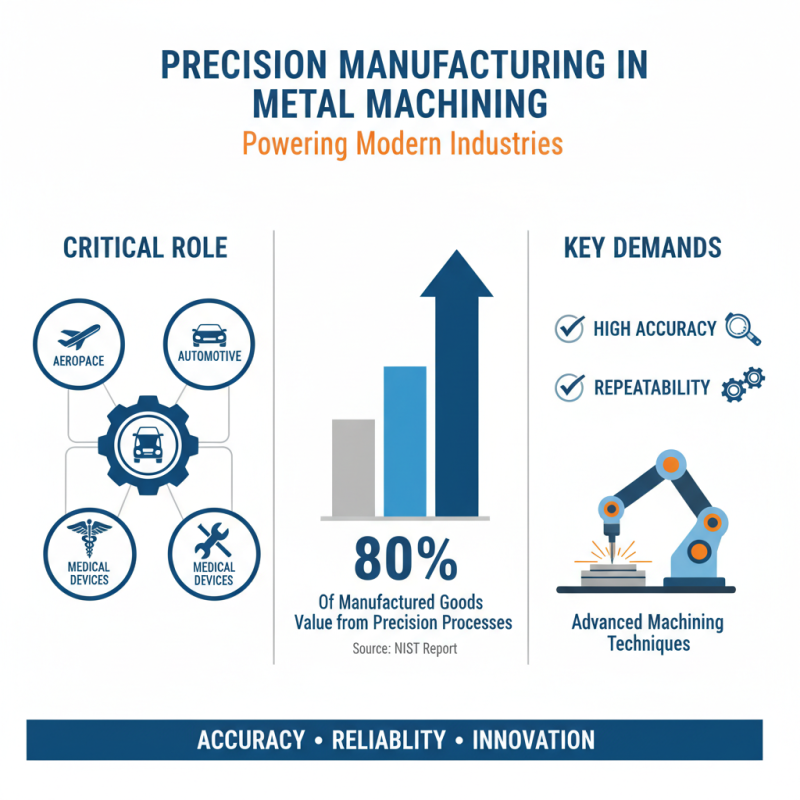

Overview of Precision Manufacturing in Metal Machining

Precision manufacturing in metal machining plays a critical role in various industries, including aerospace, automotive, and medical devices. According to a report by the National Institute of Standards and Technology (NIST), around 80% of the value in manufactured goods is attributed to precision manufacturing processes. This underscores the importance of employing advanced machining techniques to achieve the high levels of accuracy and repeatability that modern applications demand.

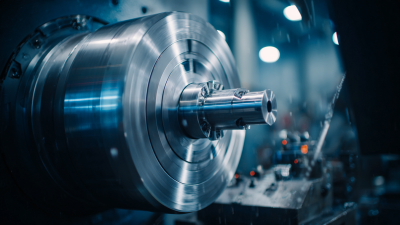

In the pursuit of precision, manufacturers often employ various machining techniques such as CNC milling, EDM (Electrical Discharge Machining), and grinding. A study by the American Society of Mechanical Engineers (ASME) highlights that precision machining can reduce production costs by up to 30% while also improving product quality. Techniques such as multi-axis machining and the use of adaptive control technologies enable manufacturers to produce complex geometries with tight tolerances, which are essential in today’s competitive market. Furthermore, the integration of Industry 4.0 practices, including real-time data analytics and automated quality control, is revolutionizing the way precision is achieved, leading to greater efficiency and reliability in manufacturing processes.

Key Machining Techniques for Achieving High Precision

Achieving high precision in machining requires a mastery of key techniques that enhance the quality and accuracy of the manufacturing process. One of the fundamental techniques is CNC machining, which utilizes computer-controlled processes to ensure consistent precision across multiple parts. This technology enables intricate shapes and designs to be produced with tight tolerances, minimizing human error and maximizing efficiency. By employing CNC milling and turning, manufacturers can achieve exceptional results in both complex and simple components.

Another critical technique is the use of advanced tooling materials. High-speed steel and carbide tools are essential for maintaining sharpness and durability during machining. These materials not only improve the longevity of the tools but also ensure high-quality finishes on machined surfaces. Additionally, implementing high-performance cutting strategies can lead to reduced cycle times while maintaining precision, giving manufacturers a competitive edge. Together, these techniques form the backbone of successful precision manufacturing, driving innovation and quality in the industry.

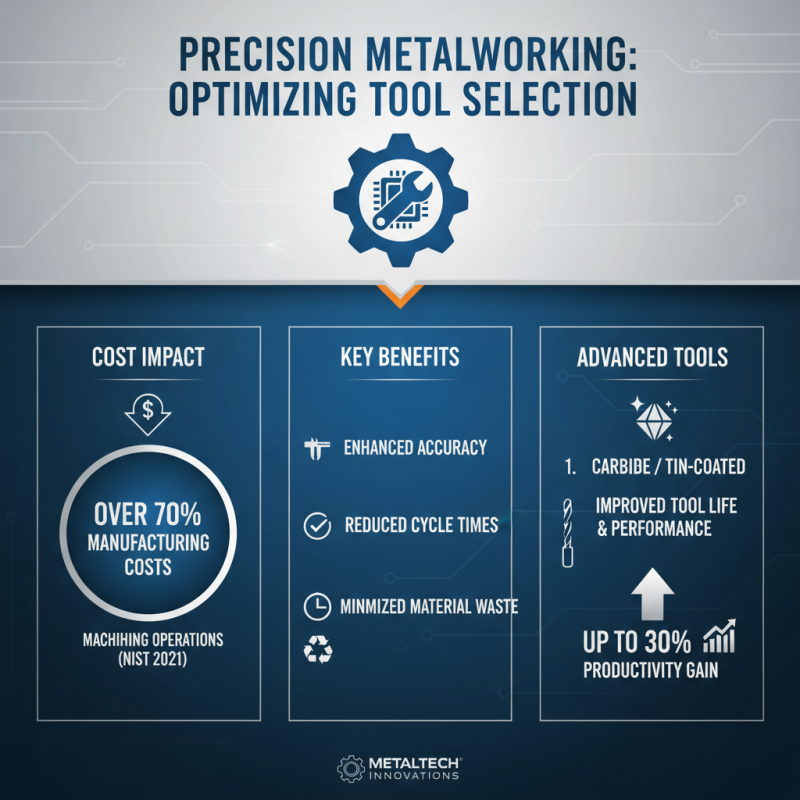

Importance of Tool Selection in Precision Metalworking

In precision metalworking, the selection of tools plays a crucial role in achieving high-quality outcomes. According to a 2021 report from the National Institute of Standards and Technology, over 70% of manufacturing costs are associated with machining operations, underscoring the importance of optimizing tool choices. The right tool not only enhances the accuracy of the machined parts but also contributes to reducing cycle times and minimizing material waste. For instance, advanced cutting tools designed with materials like carbide or coated with titanium nitride significantly improve tool life and performance, leading to up to 30% increases in productivity.

Furthermore, the integration of technology in tool selection, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, has revolutionized the precision machining landscape. A study by the Manufacturing Technology Advisory Committee indicated that companies utilizing advanced tooling technologies reported a 40% reduction in error rates and better adherence to tolerances, which are critical in sectors such as aerospace and medical device manufacturing. As the industry continues to evolve, the emphasis on tool selection will remain pivotal in driving precision manufacturing success. Adopting the latest technologies and methodologies in tool design and implementation will not only ensure superior product quality but also enhance overall operational efficiency.

Quality Control Measures in Precision Manufacturing Techniques

In precision manufacturing, quality control is paramount to ensure that machining techniques yield products that meet stringent standards. One of the fundamental quality control measures involves the implementation of statistical process control (SPC). This technique utilizes data collection and statistical analysis to monitor and control the machining processes, allowing manufacturers to identify variations and implement corrective actions promptly. By analyzing key performance indicators, manufacturers can maintain consistency in their production quality, ultimately leading to reduced waste and improved efficiency.

Another critical measure in quality control is the use of advanced inspection technologies. Techniques such as laser scanning and coordinate measuring machines (CMM) enable precise dimensional verification of machined parts. These tools help detect discrepancies between the manufactured product and its design specifications, ensuring that any deviations are addressed before products leave the production floor. Regular calibration of these inspection tools is essential to maintain their accuracy, further enhancing the reliability of the quality control process. Through these rigorous measures, precision manufacturing can achieve high levels of quality assurance, significantly contributing to the overall success of machining operations.

Future Trends in Machining Techniques for Enhanced Precision

The landscape of machining techniques is evolving rapidly, with advancements driven by technological innovations and the increasing demand for precision in manufacturing. One significant trend on the horizon is the integration of automation and artificial intelligence into machining processes. Smart machining systems, equipped with AI algorithms, can analyze performance data in real-time to optimize operational parameters, resulting in higher accuracy and reduced cycle times. This shift towards automation not only enhances productivity but also minimizes human error, a critical factor in achieving precise manufacturing outcomes.

Another notable trend is the adoption of advanced materials and hybrid machining techniques. As industries seek to produce components that are both lightweight and durable, the use of materials like composites and high-strength alloys is becoming more prevalent. Techniques such as additive manufacturing combined with traditional subtractive methods are allowing manufacturers to create complex geometries that were previously challenging to achieve. This integration of different machining approaches not only enhances precision but also expands the possibilities for product design, enabling manufacturers to push the boundaries of innovation in precision engineering.

Top 10 Machining Metal Techniques for Precision Manufacturing Success

Related Posts

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

What is Aluminium Spinning Machine and How Does it Work

-

10 Essential Tips for Mastering Metal Flow Forming Techniques

-

What is a Steel Forming Machine? A Comprehensive Guide to Understanding Its Uses and Benefits

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023