- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

Top Hot Metal Spinning Techniques for Precision Manufacturing?

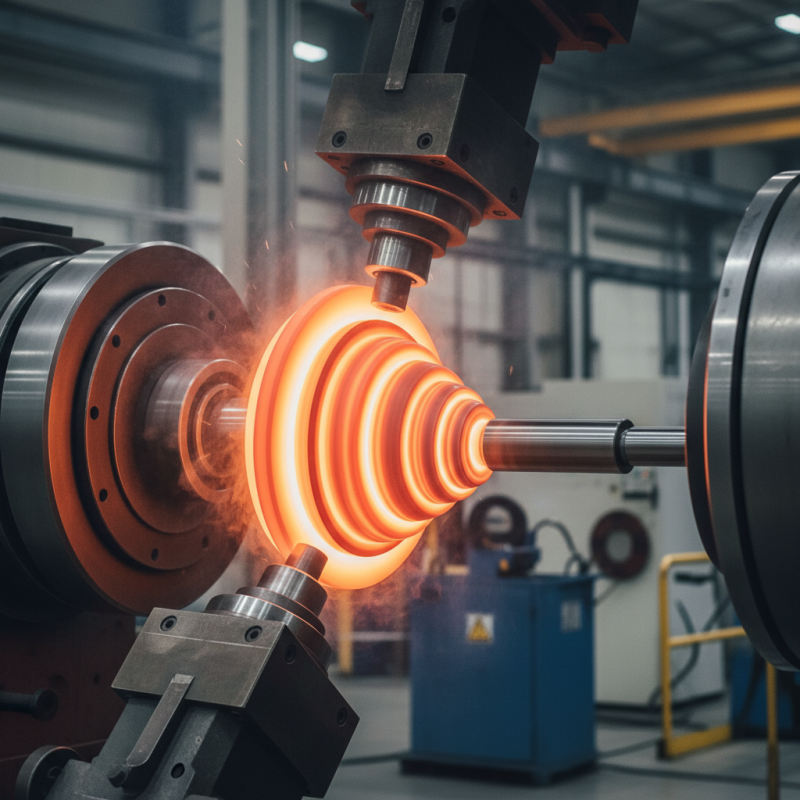

Hot metal spinning is a fascinating technique in precision manufacturing. This process shapes malleable metals into various forms. It uses high-speed rotation to transform raw material into exact components. Various industries benefit from this technology, including aerospace and automotive.

The appeal of hot metal spinning lies in its versatility. It can produce complex geometries with minimal waste. However, achieving precision can be challenging. Operators must have a keen eye for detail. Proper monitoring of speed and temperature is essential.

While hot metal spinning offers many advantages, it’s not without its flaws. Inconsistent results may arise from equipment wear or operator inexperience. Continuous improvement is vital in this field. Assessing processes regularly can lead to better outcomes. Embracing new techniques will enhance the future of hot metal spinning.

Table of Contents

[Hide]

Overview of Metal Spinning and Its Historical Significance

Metal spinning has a rich history that dates back thousands of years. This technique involves forming metal into symmetrical shapes by rotating it against a tool. Artisans of the past used simple lathes, powered by foot or hand. They crafted items like bowls and pots. Over time, metal spinning evolved alongside technology. It became a crucial method for producing various industrial components.

The significance of metal spinning lies in its versatility. It allows for the creation of components ranging from small parts to large structures. The process is often faster than other methods, like forging or milling. However, the challenge remains: achieving precision can be difficult. Experienced operators must adjust techniques based on material types and designs. Mistakes can lead to waste and require rework. In some cases, intricate designs run the risk of producing flaws, which can be costly.

Despite these challenges, metal spinning continues to play an essential role in modern manufacturing. Its historical significance cannot be overstated. The balance of artistry and technique has paved the way for innovative designs. As industries evolve, the demand for metal spinning remains strong, driving continuous improvement in this age-old craft.

Key Techniques in Metal Spinning for Precision Components Manufacturing

Metal spinning is a fascinating process that enables the production of precise components. This technique significantly enhances the manufacturing of complex shapes. During this process, a flat metal disc is transformed into a cylindrical part through rotation. High-speed spinning ensures severe plastic deformation, allowing for tight tolerances and smooth surfaces.

One critical technique in metal spinning is the use of different tooling types. Various materials can affect the final product. For instance, harder tools might improve the surface finish but could also lead to increased wear. Sometimes, the chosen strategy may not suit complex shapes, leading to potential defects. Attention must be paid, as minor tool misalignments may cause inaccuracies.

Another technique involves adjusting the temperature of the metals. Heating the metal can improve workability. However, this step requires careful monitoring. Too much heat can weaken the metal, while too little can cause cracking. Finding the right balance is crucial. Overall, while metal spinning offers precision, the techniques require constant reevaluation to avoid issues.

Top Hot Metal Spinning Techniques for Precision Manufacturing

Comparison of Traditional vs. Advanced Metal Spinning Methods

Metal spinning is a fascinating technique in manufacturing, with two main approaches:

traditional and advanced methods. Traditional metal spinning uses manual tools and often requires skilled labor.

This can lead to variations in product quality. The process typically involves shaping metal over a form using a lathe.

While this method is time-honored, it may not meet today's precision demands.

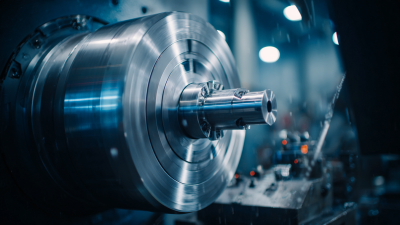

In contrast, advanced metal spinning incorporates modern technology. CNC machines allow for enhanced precision.

These machines can achieve tighter tolerances, making them suitable for complex shapes. Advanced methods also enable quicker production times, minimizing labor costs.

However, the initial investment is higher, which could deter some manufacturers.

Tips:

Focus on detail. Even small imperfections can affect product quality. Regular maintenance of machines ensures consistent performance.

Continual training of operators is key, especially when adopting new technologies. Reflecting on production processes can reveal areas needing improvement.

Balancing tradition with innovation leads to better outcomes.

Industry Applications of Metal Spinning: Case Studies and Data Insights

Metal spinning is gaining traction in various industries for its impressive versatility. The technique allows for precise shaping of metal into complex forms. Some applications include aerospace components, automotive parts, and various industrial equipment. These cases demonstrate how metal spinning ensures strength and resilience.

Take the aerospace industry, for example. It requires components with exceptional precision and durability. A case study showed that companies reduced costs and production time with metal spinning. However, challenges arise in achieving consistent quality. Minor imperfections can lead to significant issues. The automotive sector also faces similar obstacles. Here, the demand for lightweight materials meets the need for strength.

It’s crucial to continually refine spinning techniques. For instance, some manufacturers have experimented with alternative materials. This approach has shown promise yet requires rigorous testing. Insights from these industries reveal that while metal spinning has advantages, there’s room for improvement.

Future Trends in Metal Spinning: Innovations and Market Projections

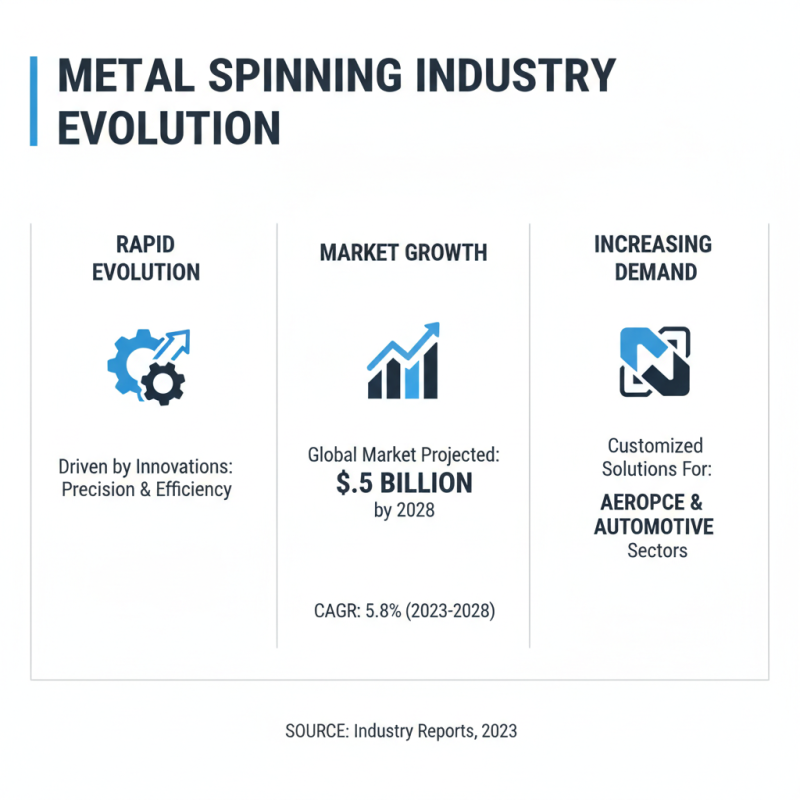

The metal spinning industry is rapidly evolving, driven by innovations that enhance precision and efficiency. Recent reports indicate that the global metal spinning market is projected to reach $3.5 billion by 2028, growing at a CAGR of 5.8%. This surge reflects the increasing demand for customized solutions in various sectors, including aerospace and automotive.

One notable trend is the integration of automated systems in metal spinning processes. Automation not only minimizes human error but also enhances production speed. For instance, automated machines can adjust techniques in real-time, ensuring consistent quality in small batches. However, as manufacturers adopt these technologies, the learning curve remains a challenge. It requires ongoing training and adaptation from skilled workers.

Sustainability is becoming a focal point in metal spinning trends as well. The industry is moving towards using eco-friendly materials and processes. Reports show that 70% of manufacturers are exploring ways to reduce waste. Yet, despite these strides, there’s still a long way to go. Current practices sometimes fall short of ideal sustainability standards. Manufacturers must continuously reassess their methods to align with stricter environmental guidelines while maintaining efficiency.

Related Posts

-

Best Tips for Efficient Denn Metal Spinning: Techniques and Benefits Explained

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions

-

10 Essential Tips for Mastering Metal Spinning Roller Techniques?

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023

-

Why Choose Metal Forming Inc for Your Manufacturing Needs

-

10 Essential Tips for Mastering Metal Flow Forming Techniques