- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- News & Updates

- Contact / Info / Service

- Home

- Machinery

- Metal Spinning Machines

- Flow Forming Machines

- Wheel Forming Machines

- Shear Forming Machines

- Necking-In / Closing Machines

- Rotary Forging Machines

- Pulley Forming Machines

- Trimming, Beading,… Machines

- Circular and Ring Shears

- Custom Machines and R&D

- Robotics, Loading & Unloading

- Upgrades – Used – Retrofits

- DENN Software / Technologies

- Machinery Technologies

- Applications & Industries

- Lubricants

- Blog

- Contact / Info / Service

How to Use Flow Forming Steel for Maximum Strength and Durability

In the realm of advanced manufacturing, flow forming steel stands out as a pivotal material known for its unparalleled strength and durability. As technology continues to evolve, industries are keenly interested in optimizing the use of this innovative material. According to industry expert Dr. Lisa Reynolds, a renowned material scientist, "Flow forming steel not only enhances product performance but also improves the overall lifespan of components, making it an ideal choice for demanding applications."

The unique properties of flow forming steel, resulting from its precise processing techniques, allow for greater structural integrity while minimizing material waste. This process not only contributes to sustainability in manufacturing but also meets the rigorous demands of modern engineering. By understanding the essential methods to utilize this material effectively, manufacturers can harness its full potential, ensuring that products meet both safety and performance standards.

In this discussion, we will explore best practices and innovative applications of flow forming steel, shedding light on how companies can leverage its benefits to achieve maximum strength and durability in their products. As we delve into this topic, it becomes clear that mastering the use of flow forming steel could redefine the benchmarks for quality in various industries.

Table of Contents

[Hide]

Understanding Flow Forming Steel and Its Properties

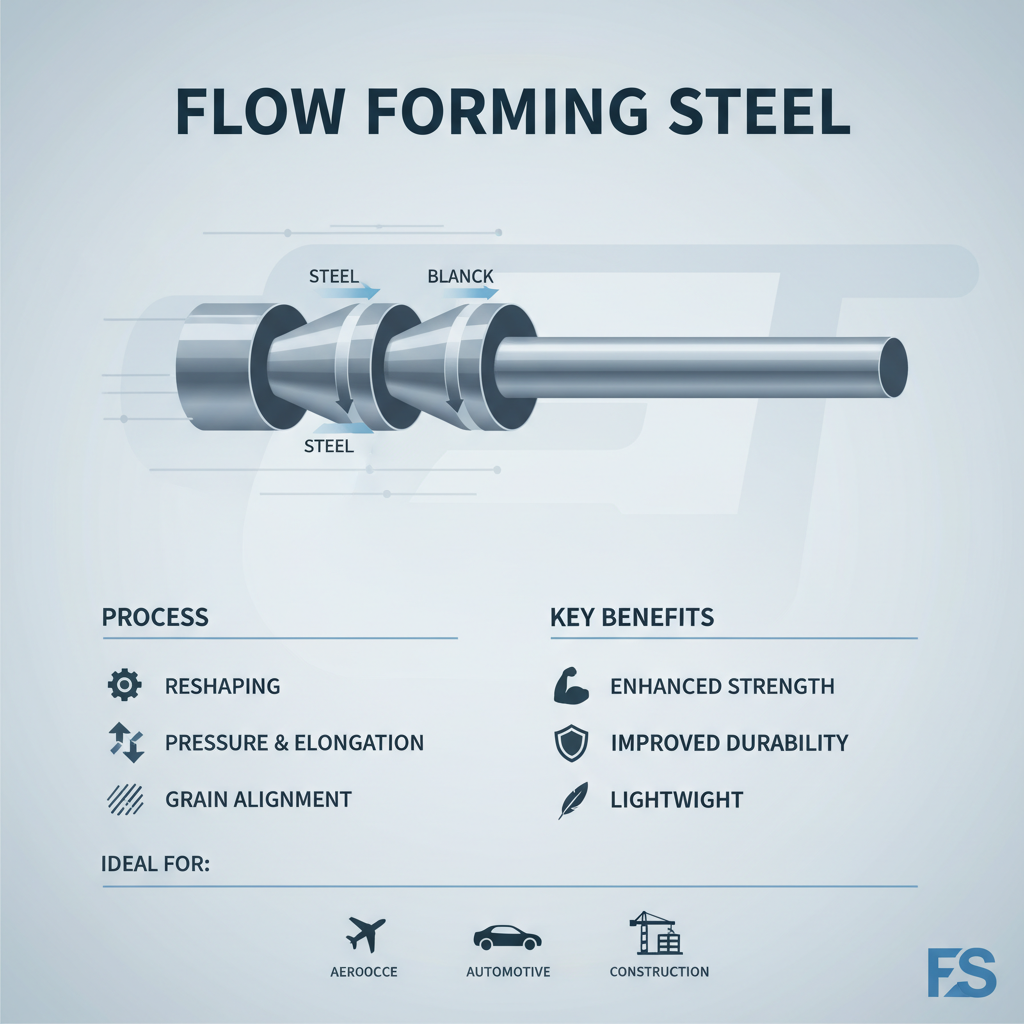

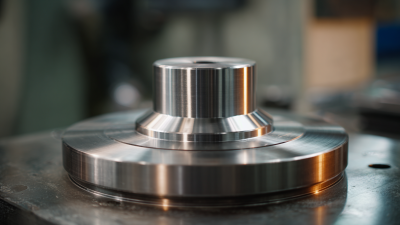

Flow forming steel is a unique manufacturing process that significantly enhances the mechanical properties of steel products. This technique involves reshaping a steel blank through a series of rollers, which exerts pressure and elongates the material. As the steel is thinned and shaped, its grain structure becomes more aligned and refined, resulting in improved strength and durability. The process not only enhances the tensile strength of the steel but also maintains its lightweight characteristics, making it ideal for applications in aerospace, automotive, and construction industries.

One of the critical properties of flow forming steel is its exceptional resistance to fatigue and wear. The controlled deformation during the flow forming process increases the hardness of the steel, allowing it to withstand harsher operational conditions without succumbing to deformation or fracture. Additionally, flow forming allows for precise tolerances and complex geometries, which opens up possibilities for innovative designs. The refined material properties combined with these manufacturing advantages position flow formed steel as a premier choice for engineers and manufacturers seeking components that demand high performance and longevity.

The Process of Flow Forming: Techniques and Equipment

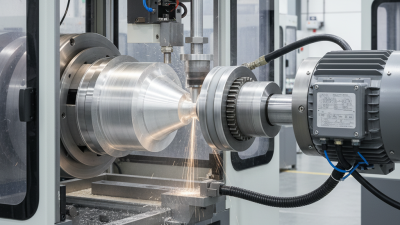

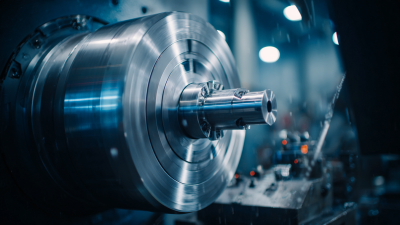

Flow forming is a precision metalworking process that enhances the strength and durability of steel components through a series of controlled deformation techniques. This method begins with a pre-formed blank, which is mounted on a lathe. As the blank is rotated, specialized rollers apply axial and radial forces, elongating and thinning the material. This process not only shapes the component into its desired form but also significantly improves its mechanical properties due to strain hardening.

The equipment utilized in flow forming plays a critical role in achieving optimal results. A typical flow forming machine consists of a spinning lathe, rollers, and various control systems to monitor temperature and pressure throughout the process. Advanced CNC technology allows for precise control of the rollers' movements, ensuring consistent thickness and material integrity. By leveraging these techniques and state-of-the-art equipment, manufacturers can produce high-strength steel components that meet stringent performance specifications, making flow forming a preferred choice in industries such as aerospace, automotive, and construction.

Key Benefits of Using Flow Forming for Strength and Durability

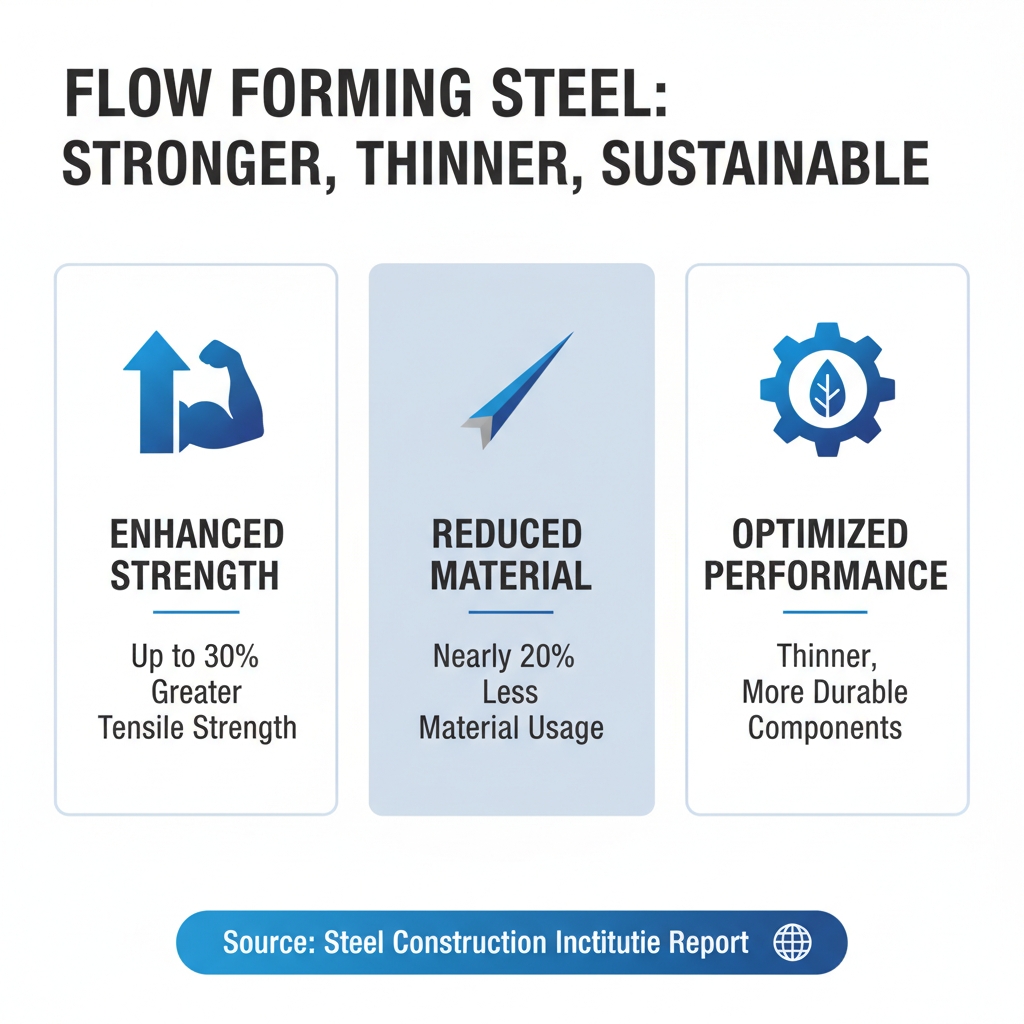

Flow forming is a highly efficient manufacturing process that significantly enhances the strength and durability of steel components. One of the primary benefits of this technique is its ability to produce thinner yet stronger parts compared to traditional methods. According to a report by the Steel Construction Institute, components subjected to flow forming can exhibit up to 30% greater tensile strength, while reducing material usage by nearly 20%. This not only contributes to a more sustainable manufacturing approach but also optimizes performance in demanding applications.

Furthermore, flow forming improves the microstructure of the steel, creating a refined grain pattern that enhances fatigue resistance. The International Journal of Mechanical Sciences has documented that flow-formed components tend to have a higher resistance to stress and deformation under load, making them ideal for use in the automotive and aerospace industries. For instance, components such as axles and wheel rims produced through this method have been shown to endure up to 50% more cyclic loading before failure compared to conventionally manufactured alternatives. This ensures longevity and reliability, crucial for applications where safety and performance are paramount.

Applications of Flow Formed Steel in Various Industries

Flow formed steel, known for its remarkable strength and durability, finds application across various industries. One notable area is automotive manufacturing, where flow formed components are utilized to create lightweight yet robust structures. These components, crafted through a process that elongates steel into specific shapes, provide enhanced performance in safety and fuel efficiency.

In the aerospace sector, flow formed steel is used for critical components like landing gear and structural frames. The high strength-to-weight ratio of flow formed steel helps in reducing overall aircraft weight while maintaining safety standards. This makes it a preferred choice when every ounce counts.

**Tip:** When considering flow formed steel for your project, always assess the specific requirements of your application, including load-bearing needs and environmental conditions.

Additionally, the oil and gas industry leverages flow formed steel for drilling equipment and pipelines. The ability of this steel to withstand extreme pressures and temperatures ensures reliability in harsh environments.

**Tip:** Engage with experienced suppliers to explore custom flow forming options, which can lead to tailored solutions that meet unique operational demands.

Maintenance and Care for Flow Formed Steel Components

Flow formed steel components are known for their exceptional strength and durability, but maintaining these elements is crucial to ensure their longevity and performance. Regular inspections should be carried out to identify any signs of wear or corrosion. According to a report by the American Institute of Steel Construction, routine preventive maintenance can extend the lifespan of steel products by up to 25%. Simple practices such as cleaning the surface regularly and addressing any surface blemishes promptly can significantly mitigate corrosion risks.

Moreover, proper storage and handling of flow formed steel components are essential. Industrial studies indicate that the environment in which these components are stored can greatly affect their performance. For instance, steel exposed to high humidity and harsh chemicals may suffer from oxidation, leading to compromised structural integrity. Utilizing protective coatings, as recommended by the Steel Construction Institute, can further enhance protection against environmental factors, ensuring that flow formed components maintain their mechanical properties over time. Emphasizing these maintenance strategies not only safeguards the initial investment but also contributes to safety and reliability in applications where flow formed steel components play a critical role.

Strength and Durability Comparison of Flow Formed Steel vs. Traditional Steel

Related Posts

-

What is Aluminium Spinning Machine and How Does it Work

-

10 Essential Tips for Optimizing Flow Forming Metal Techniques

-

2025 Top Digital Metal Machining Equipment Trends You Need to Know

-

Top 5 Metal Roll Forming Machines for Precision Manufacturing in 2023

-

The Essential Guide to Forming Metal: Techniques, Applications, and Market Insights in 2023

-

Discover the Future of Industry with Advanced Global Metal Spinning Solutions